In the dynamic landscape of the manufacturing industry, traditional approaches to quality control, efficiency, and predictive maintenance have long presented significant hurdles. However, a new era is dawning, exemplified by trailblazers like Atlantis Foundries. Under the visionary leadership of CEO Peter du Plessis, Atlantis Foundries has not just embraced but masterfully integrated AI-driven predictive analytics, fundamentally transforming its production processes, elevating quality standards, and drastically reducing defects.

This remarkable journey is a testament to How Atlantis Foundries Leveraged AI for Manufacturing Excellence, positioning itself not just as a participant, but as a global leader in smart manufacturing. This case study delves into how AI has become an indispensable and transformative tool for their operations.

Establishing a robust AI‑powered data model

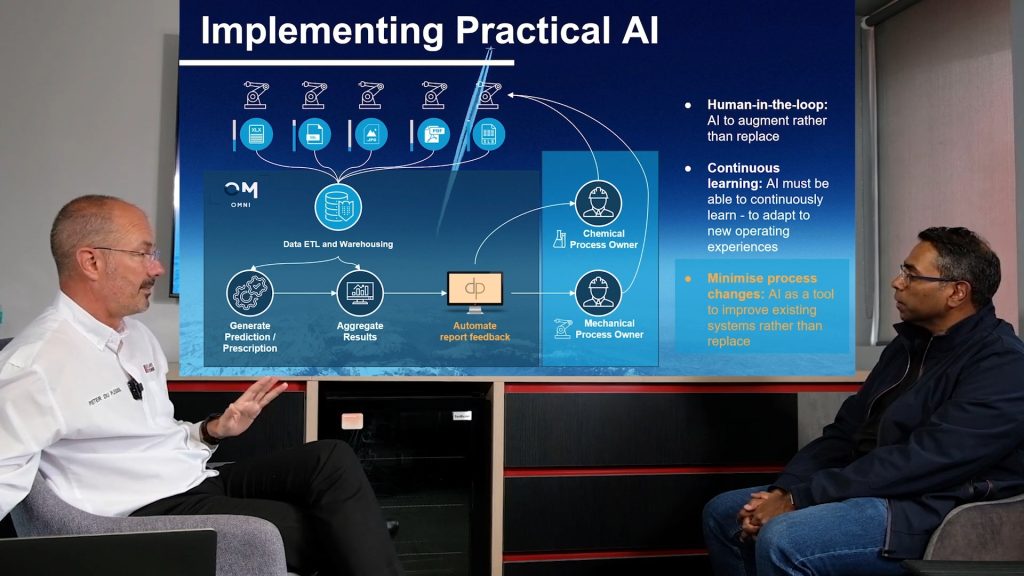

For artificial intelligence to truly unlock its potential, it demands a foundation of structured and meticulously integrated data. Recognizing this critical prerequisite, Atlantis Foundries embarked on developing a comprehensive data model. This robust framework allows them to capture, process, and analyze vast amounts of production data, leading to significantly improved decision-making and optimized manufacturing processes. This approach aligns perfectly with broader Industry 4.0 findings, which emphasize that integrated data ecosystems are absolutely foundational for successfully leveraging machine learning and AI-driven automation, as highlighted in research from MDPI.

The success of Atlantis Foundries’ data model rests on several key components:

- Standardizing Data Collection: A cornerstone of their strategy involves ensuring that all suppliers and machinery produce data in a consistent, structured format. This meticulous alignment with Industry 4.0 data governance strategies, detailed in papers like the one on arXiv.org, is crucial for data integrity.

- Integration with Equipment: To future-proof their operations, new equipment procured by Atlantis Foundries is mandated to meet specific data output standards. This proactive measure significantly enhances the interoperability and longevity of their sophisticated AI systems.

- Building a Centralized Data Hub: All production data at Atlantis Foundries is aggregated into a unified model, creating a centralized data hub. This best practice, essential for successful industrial AI deployments, enables real-time analytics and is thoroughly discussed by Robotic Innovations.

With these robust data structures firmly in place, their AI systems can efficiently analyze both historical and real-time data, providing unparalleled insights to detect inefficiencies, support agile decision-making, and continuously optimize workflows.

The role of AI in predictive quality control

Historically, quality control in foundries has been a challenging domain, largely reliant on manual inspection methods and basic statistical process control tools. These traditional approaches were inherently reactive and highly susceptible to human error and significant delays, often culminating in higher scrap rates and inconsistent output, as detailed in an Eman Research publication.

Atlantis Foundries has fundamentally transformed this paradigm by implementing an advanced AI system that actively monitors over 6,500 production processes simultaneously. This sophisticated capability enables the real-time detection of anomalies, empowering operators to address potential issues proactively before they escalate into costly defects. This mirrors significant advancements in deep learning applications for automated inspection, which have achieved remarkable accuracy rates exceeding 99% in complex casting environments, as shown by research on PMC.

The benefits of this AI-driven approach are multifaceted:

- AI‑Driven Anomaly Detection: The continuous scanning of process variables provides an unparalleled ability to identify deviations instantly, enabling immediate and proactive corrections.

- Prescriptive Analytics: Moving beyond simple fault reporting, the system offers precise, data-backed recommendations for corrective actions. This eliminates guesswork for operators, streamlining the resolution process.

- Near‑Zero Defect Production: Through the power of predictive analytics, Atlantis Foundries has dramatically reduced its defect rates. This positions the company closer to the ambitious goal of zero-defect manufacturing, a feat increasingly realized in similar industrial settings through advanced deep learning and neural networks.

As Peter du Plessis himself emphasized in a recent interview (YouTube), these profound transformations would simply not have been possible without first establishing a robust and intelligent data foundation.

Conclusion

The journey of Atlantis Foundries clearly illustrates the immense potential of AI in revolutionizing traditional manufacturing. By meticulously building a robust data infrastructure and strategically deploying AI for predictive quality control, Atlantis Foundries has not only overcome long-standing industry challenges but has also set a new benchmark for operational excellence and product quality. Their pioneering efforts in integrating AI demonstrate a forward-thinking approach that promises continued innovation and leadership in the global smart manufacturing landscape. As industries worldwide look towards Industry 4.0, Atlantis Foundries stands as a powerful case study, proving that with the right vision and technological integration, a future of highly efficient, near-zero defect production is not just a dream, but an achievable reality.