Component Assembly Solutions

Every specialised machine and automotive component assembly system is designed and built to meet specific customer requirements, with a focus on cost-effectiveness, quality, efficiency and sustainability.

- COMPLEXITY

Manual to fully automated

Jendamark strives to develop the right fit for your market, offering a range of manual, semi-automated and fully automated solutions to ensure unmatched precision and repeatability.

We have delivered on every level of complexity – from a fully manual engine assembly line in India to a lights-out catalytic converter assembly line in Germany.

Manual

Semi-Automated

Fully Automated

Powertrain | Catalytic Convertor | EV | General Assembly | Aerospace

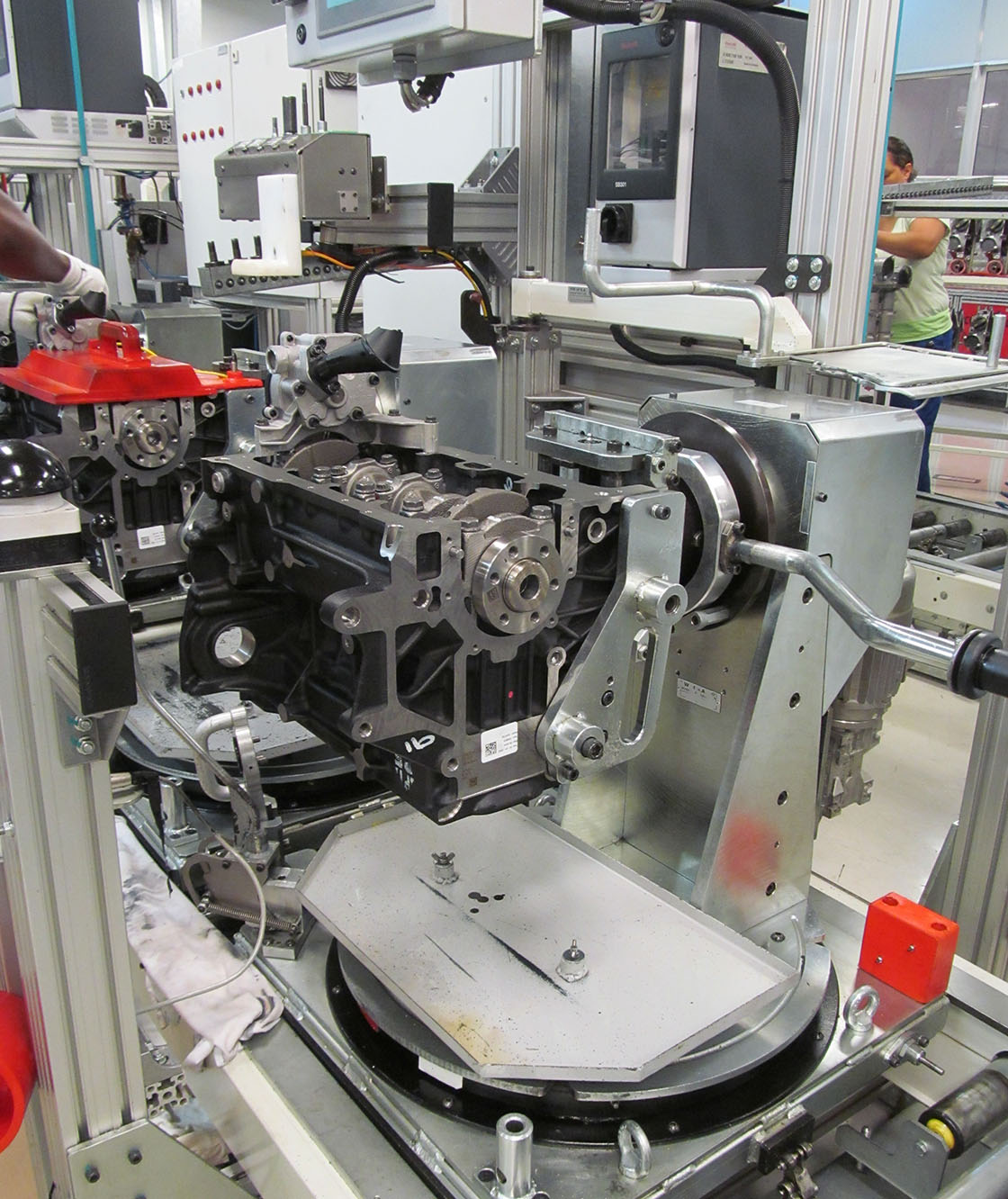

Powertrain

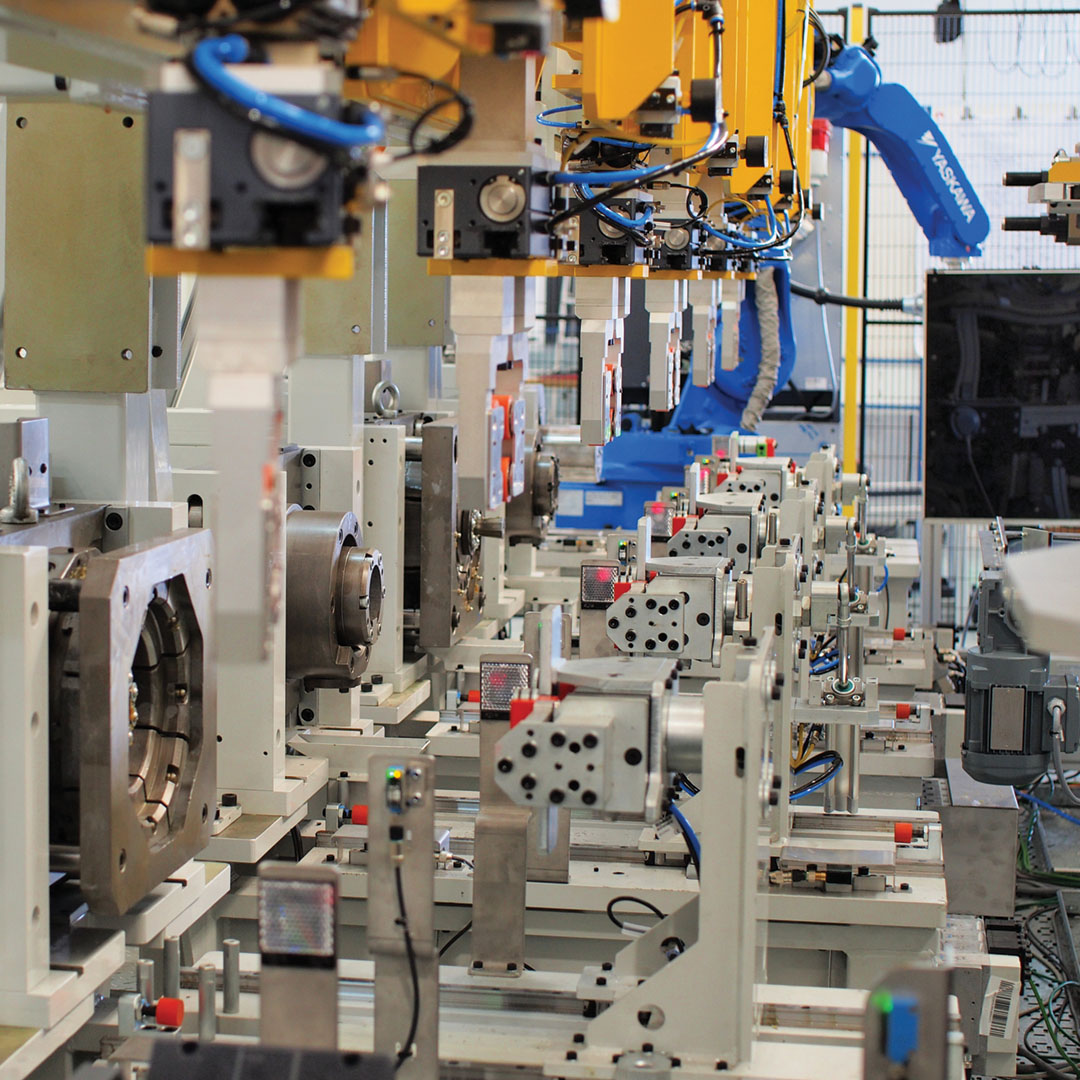

Catalytic Converter Assembly

Electric Vehicles

General Assembly

Aerospace

Jendamark builds turnkey automotive assembly systems and production lines for all aspects of the powertrain system.

Every solution is designed to meet specific customer requirements.

From modular canning lines to lights-out catalytic converter assembly systems, Jendamark has developed a range of flexible, automated solutions to help customers keep pace with changing emissions standards and product requirements.

Aside from our core expertise in powertrain, catalytic converter and new energy vehicle assembly systems, Jendamark is also able to harness our technologies and capabilities to design and build solutions for a variety of automotive components.

Jendamark offers a range of advanced tooling and fixtures, as used by leading aerospace manufacturers. All tools are designed and fabricated – using superior raw materials – for easy installation, long service life, low maintenance and high performance.

- Modular approach

Building blocks for assembly lines

Our modular approach allows us to customise and combine our basic building block machines – refined over three decades of creating automation solutions – and make them work for you.

Building on our proven track record in the passenger and commercial vehicle sector, we have expanded our offering to serve heavy-duty, off-road vehicles for the mining and agricultural sectors.

- CAPABILITIES

Building Blocks for Engineers: Save with Standardised Machines

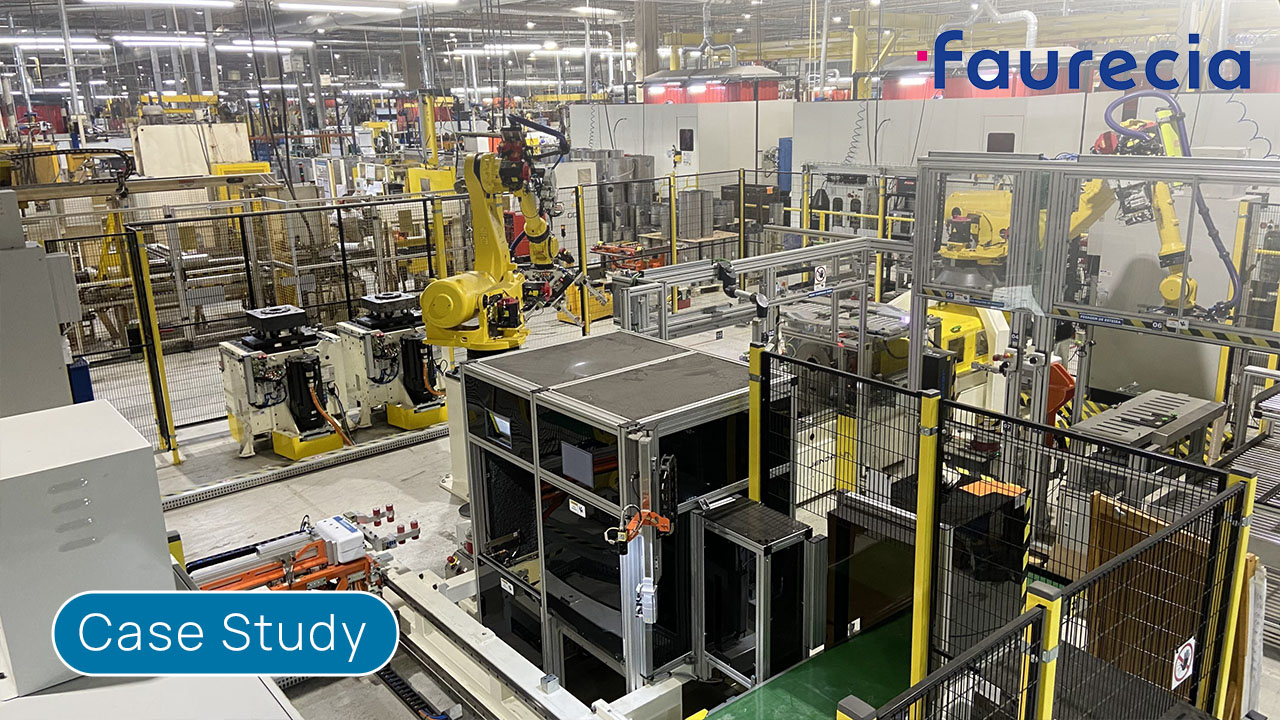

See how our approach helped Faurecia achieve:

- 20% cost reduction in delivering the line

- 50% reduction in operator training time

- 30% reduction in project delivery time