Our Approach

Building Blocks

Jendamark works with the customer towards the shared goal of achieving long-term standardisation of machines and avoiding short-term technical and commercial decisions that cost more in the long run.

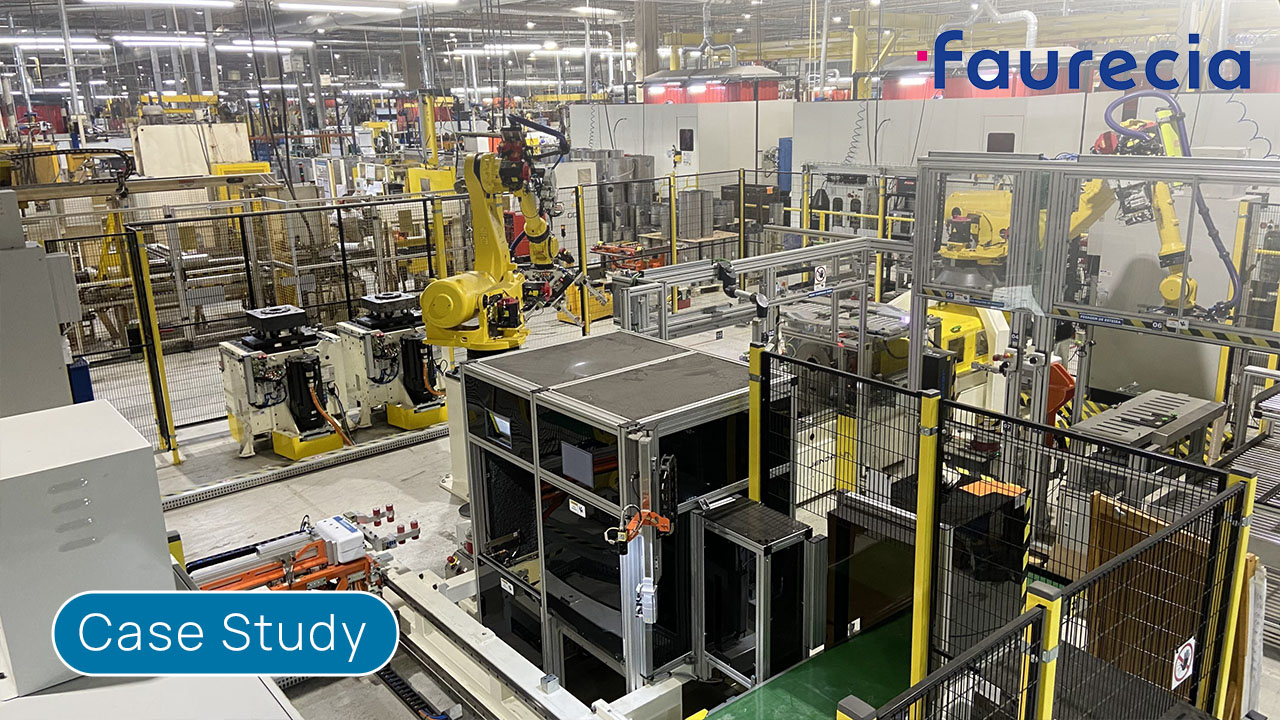

- CASE STUDY

Building Blocks for Engineers: Save with Standardised Machines

See how our approach helped Faurecia achieve:

- 20% cost reduction in delivering the line

- 50% reduction in operator training time

- 30% reduction in project delivery time

Our Modular Methodology

Selecting a supplier for an assembly line can be daunting. Who do you choose when you need a cost-effective, standardised assembly line that also allows for flexibility and future scalability in response to production changes?

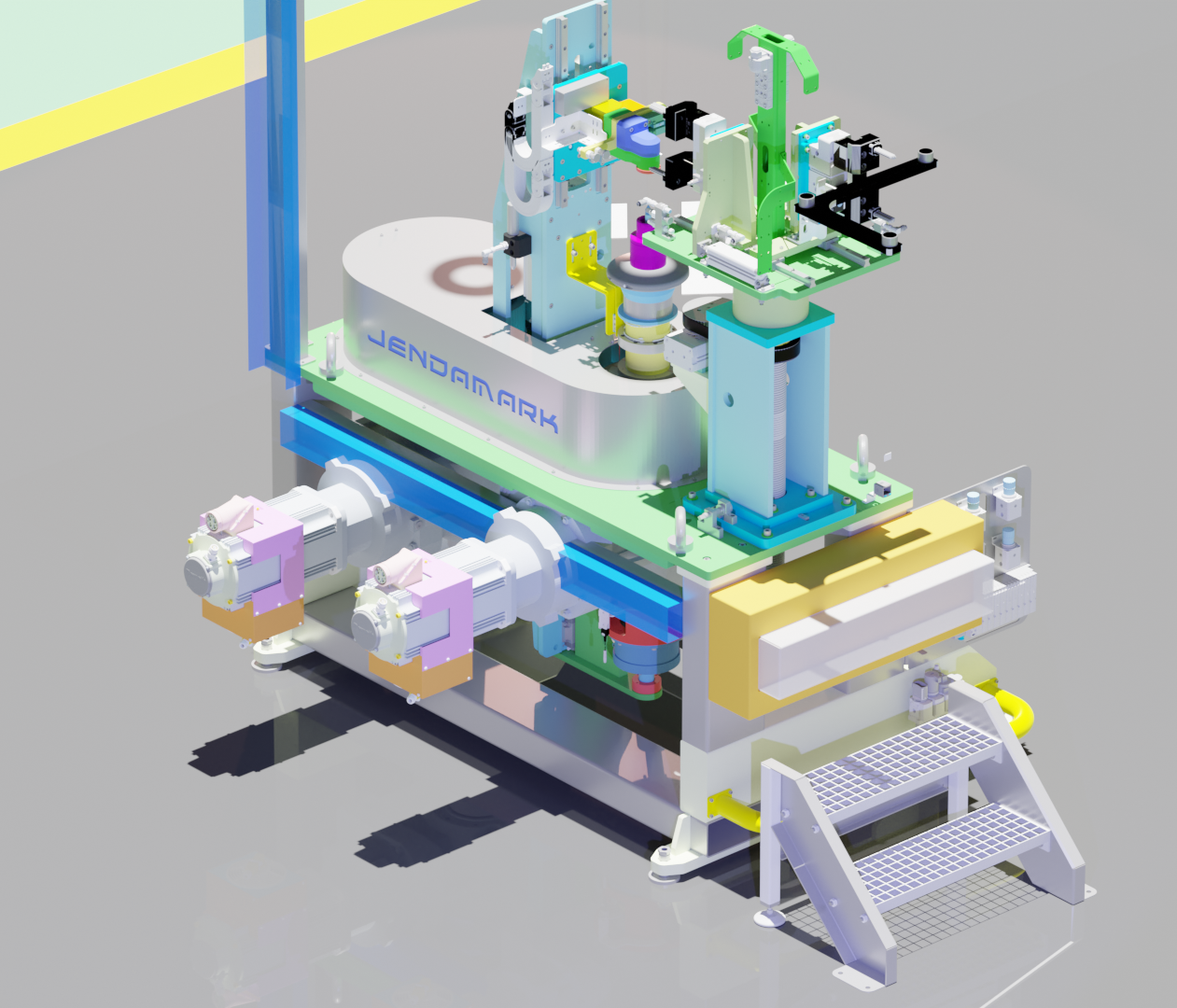

Jendamark harnesses three decades of experience and learnings from previous projects to inform our building block methodology. This approach has helped our customers save resources and mitigate risks.

How We Approach a Project

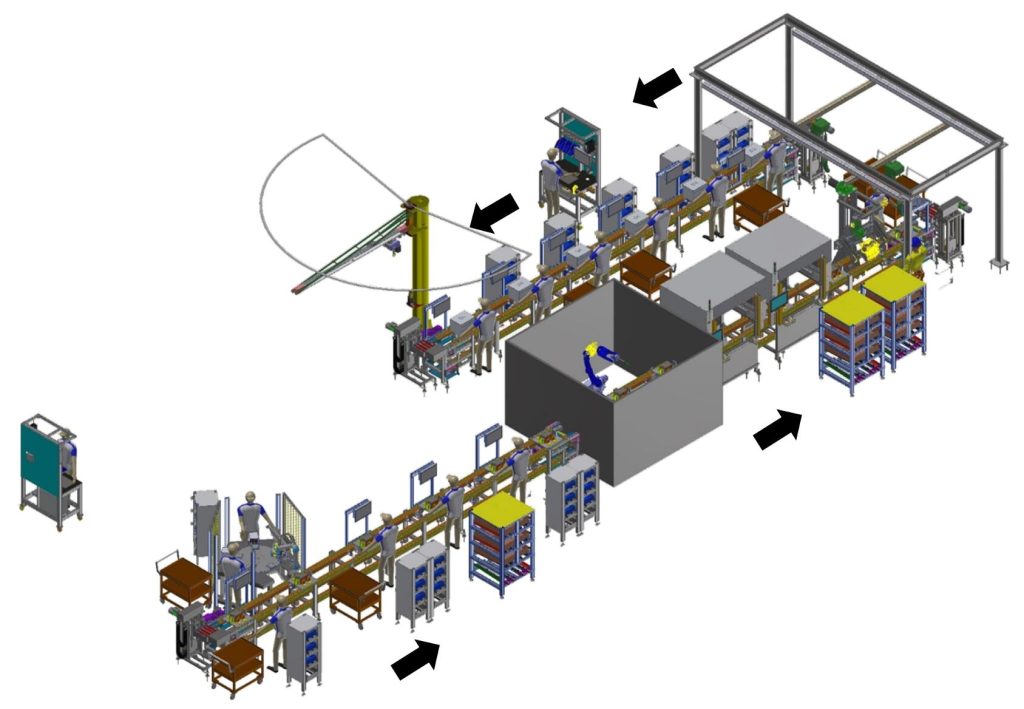

- We consider the customer’s immediate and long-term goals with insight from their teams to customise and build the most modular and flexible machines that can be configured and reconfigured to meet the varying global production demands.

- Once we have the building blocks, we design the line and focus on optimising line-specific requirements such as layout, cycle time, floor space and head count.

- We develop the first assembly lines to standardise critical machines and processes as the standard building blocks for all future assembly lines.

Benefits of Standardised Machines

Reduced design time: A standard machine requires minimum design, resulting in a reduced cost and quicker release time. Machines can be configured into various levels of automation.

More time: Available to optimise layouts, ergonomics and logistics planning, for long-term savings.

Increased machine reliability: Machines are tried and tested. Improvements can be made in a controlled manner, with the risk of changes understood and managed.

Reduced operator and technician training: Teams, once familiar with the standard machine, will not have to relearn a new machine for each project.

Faster installation and ramp-up time: Due to familiarity, machines will be installed and commissioned faster.

Stock on hand: We can build up a store of standard machines to supply a customer with a machine within weeks of request.

Process standardisation: Process experts can manage, implement and deploy standardised assembly processes globally from a central planning team.

“With the first project we develop the standard machines, thereafter we fix the base design and base pricing. We save significant time, effort and money.”

Tier 1 Global Planning Manager

See how building blocks work in the real world

Learn how applying this approach cut a customer’s canning line costs by 20%.