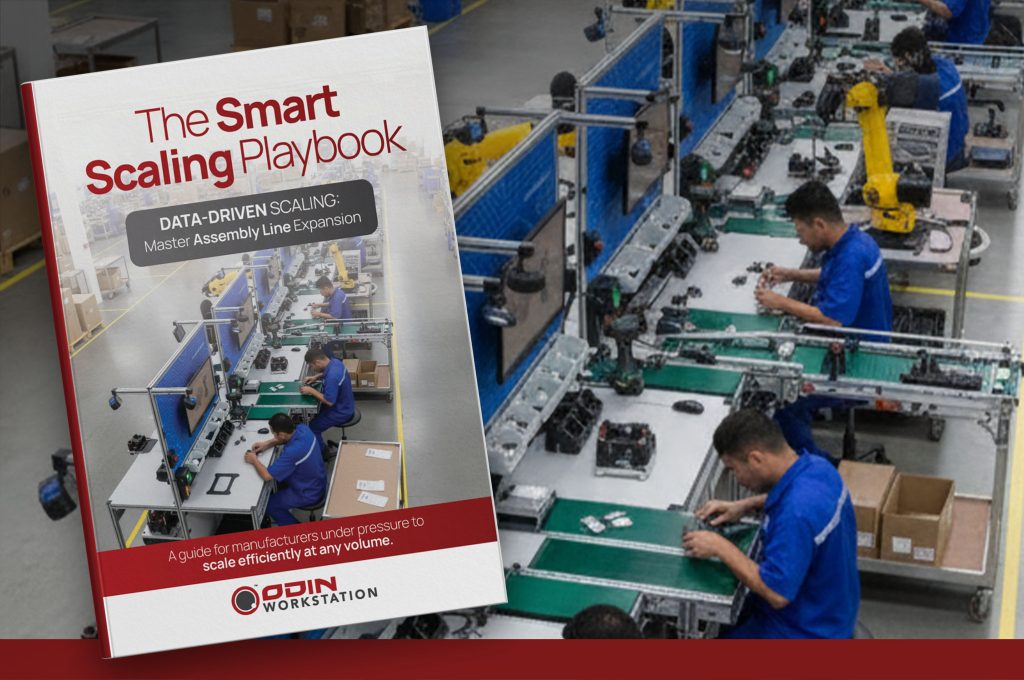

The pressure on modern manufacturers to increase output while maintaining quality has never been greater. Yet many factories are unknowingly sitting on massive untapped potential on their assembly line. Jendamark’s latest publication — The Smart Scaling Playbook — shows discrete manufacturers how to unlock that capacity before investing in new machinery or increasing their headcount.

Beyond traditional scaling: The power of data

Scaling production has traditionally meant adding more people, machines, or floor space. But as Jendamark’s ODIN Workstation team explains, this approach often leads to diminishing returns. This is known as the Scaling Trap. While it may feel like progress, without fixing underlying inefficiencies like operator variability and process errors, this approach can multiply existing problems.

The smarter path lies in using data to optimise what you already have.

Unlock hidden capacity: Get the benefits of data-driven assembly

The Smart Scaling Playbook: A Practical Guide to Data-Driven Assembly Growth outlines how digital work instructions, operator guidance, and traceability can reveal and reclaim up to 40% of hidden capacity. Through real factory examples, the guide demonstrates how ODIN Workstation has helped manufacturers:

- Cut training time from weeks to days

- Improve product quality through live traceability

- Identify and remove hidden bottlenecks in real time

- Scale confidently up or down based on accurate production data

Developed by Jendamark’s automation experts, ODIN Workstation brings a new level of intelligence to the assembly line. It connects people, processes, and machines into one streamlined system, enabling data-driven decision-making that strengthens productivity and resilience.

Whether you’re managing a high-volume automotive assembly line or building prototypes for a new product, the Smart Scaling Playbook is an essential read. Download it today to discover how your facility can scale smarter, not bigger.