Despite the tangible promise of Industry 4.0, many digital transformation projects simply don’t deliver real, lasting value. The problem? The absence of a unified digital architecture that should give manufacturers control over their own data – and the flexibility to scale.

Over the past two decades, we’ve toured factories across the globe and partnered with manufacturers at various points along their digital journeys. A recurring challenge emerges: every machine vendor brings their own digital strategy. Their own analytics tools. Their own dashboards. Their own protocols.

While each solution is effective in its own right, this fragmented landscape of proprietary systems creates a big problem. Collecting and processing data in isolation makes integration difficult, if not impossible. The result is that critical data is trapped in silos, rendering it useless for plant-wide optimisation.

This isn’t just a technical limitation – it’s a strategic risk.

To mitigate this risk, we proposed a different approach at a recent strategy session with a large multinational manufacturing company.

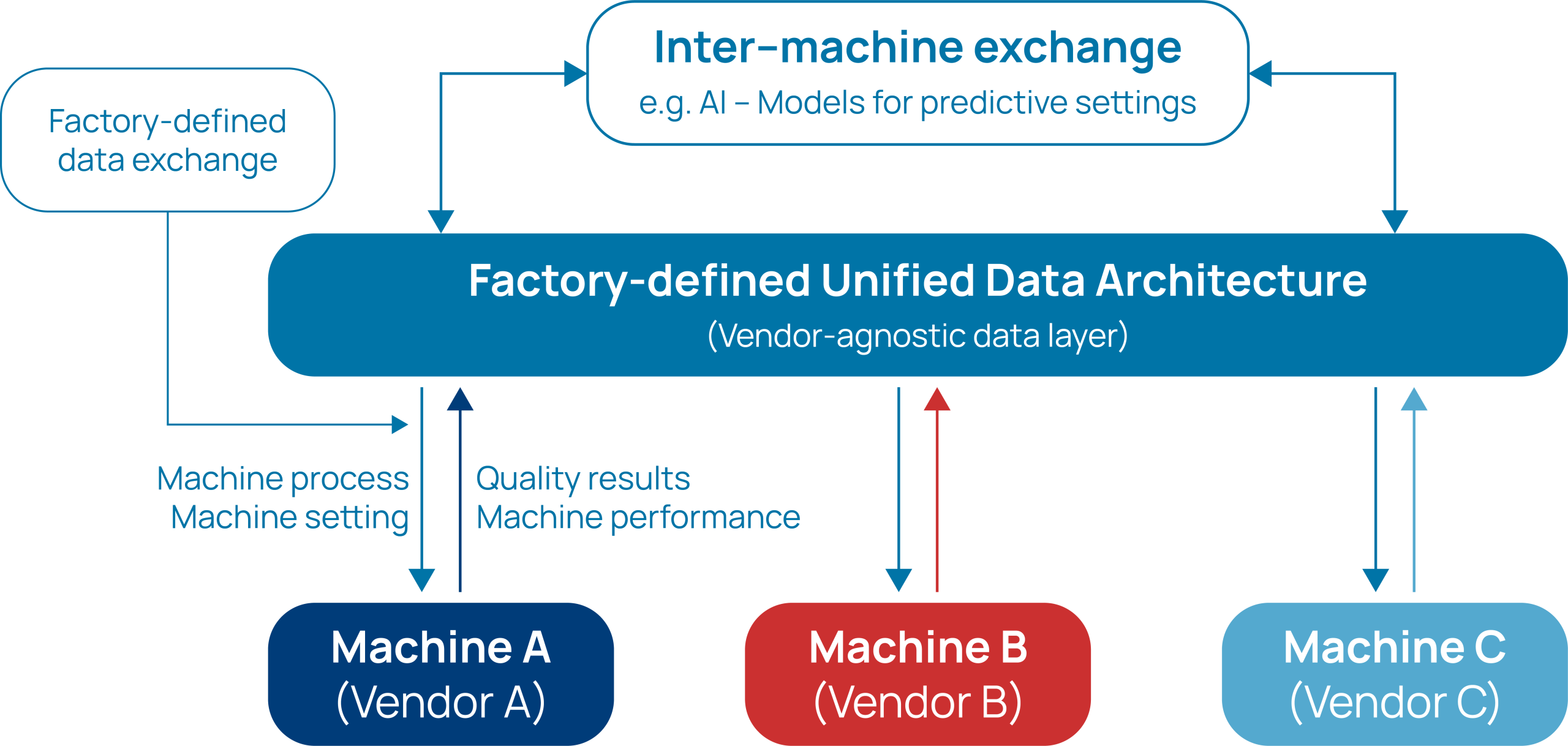

It starts with smart architecture – building a unified, vendor-agnostic data layerthat acts as the digital backbone of the factory. Instead of machines being locked to fixed settings, each asset – whether a filler, press, or test bench – should be designed to interface with a central data model.

On startup, the machine sends queries to the system about targets – such as weights, speeds, tolerances and sequences – and receives those from the centralised database.

After the operation, it returns performance, quality, and downtime data to the same system. This structure allows Machine A to inform Machine B – even if they come from different vendors – because they’re all communicating through the same digital infrastructure.

This foundation is critical to enabling:

Without this architecture, even the most advanced AI predictions have no pathway to influence real-world operations.

Here’s the harsh truth: many leadership teams don’t yet grasp the importance of digital architecture as the point of departure.

Too often, digital investments focus on surface-level wins – a dashboard here, a sensor there. But without a cohesive supporting framework, these efforts remain isolated. They fail to scale, and the long-term impact never materialises.

This is why digital transformation needs board-level attention. Architecture is a strategic asset – not an IT line item.

Boards need technically informed voices who understand interoperability, data ownership, and platform design.

Our proposition is this: From the outset, factories must define the data standards like any other machine specification.

Every new machine must:

This puts the control back in the hands of the manufacturer. The plant, not the OEM, owns the master data, recipes, and logic. This reduces vendor dependency, boosts flexibility, and enables cross-line optimisation.

This approach doesn’t require a full digital overhaul from day one. It can grow incrementally. Here’s how to begin the process:

The goal is to establish a shared language for your machines, systems, and teams – a digital foundation that grows with your operations.

Much like electricity or compressed air, data must become a utility in modern factories. It should flow freely, be universally available, and serve every function – from operations to engineering to quality assurance.

Until manufacturers take control of this layer, they will remain at the mercy of vendor constraints. But by building a vendor-neutral, interoperable architecture, they unlock a future of real-time insight, adaptive control, and continuous improvement.

The foundation of smart manufacturing is not a dashboard – it’s data ownership.

Check out our other Resource sections:

Sign up to get the latest thought leadership articles – written by our experts – delivered straight to your inbox.