With global markets undergoing seismic shifts, and manufacturers under pressure to respond with speed and resilience, smart factories should already be equipped and agile enough to adapt and deliver.

But, despite having access to some of the most advanced manufacturing technologies in history – from AI-powered quality checks to fully connected production lines – many factories have yet to see transformative improvements in productivity, quality, and efficiency.

From my vantage point heading up digital innovations at Jendamark Automation, the reason is clear: technology alone isn’t enough.

In our experience – building everything from manual to semi- and fully automated production systems for automotive manufacturers worldwide – the real barrier is human behaviour.

When companies “go digital,” they often expect instant results. But my personal experiences off the factory floor show that insight without action changes nothing.

Let’s head to the golf course for my first example.

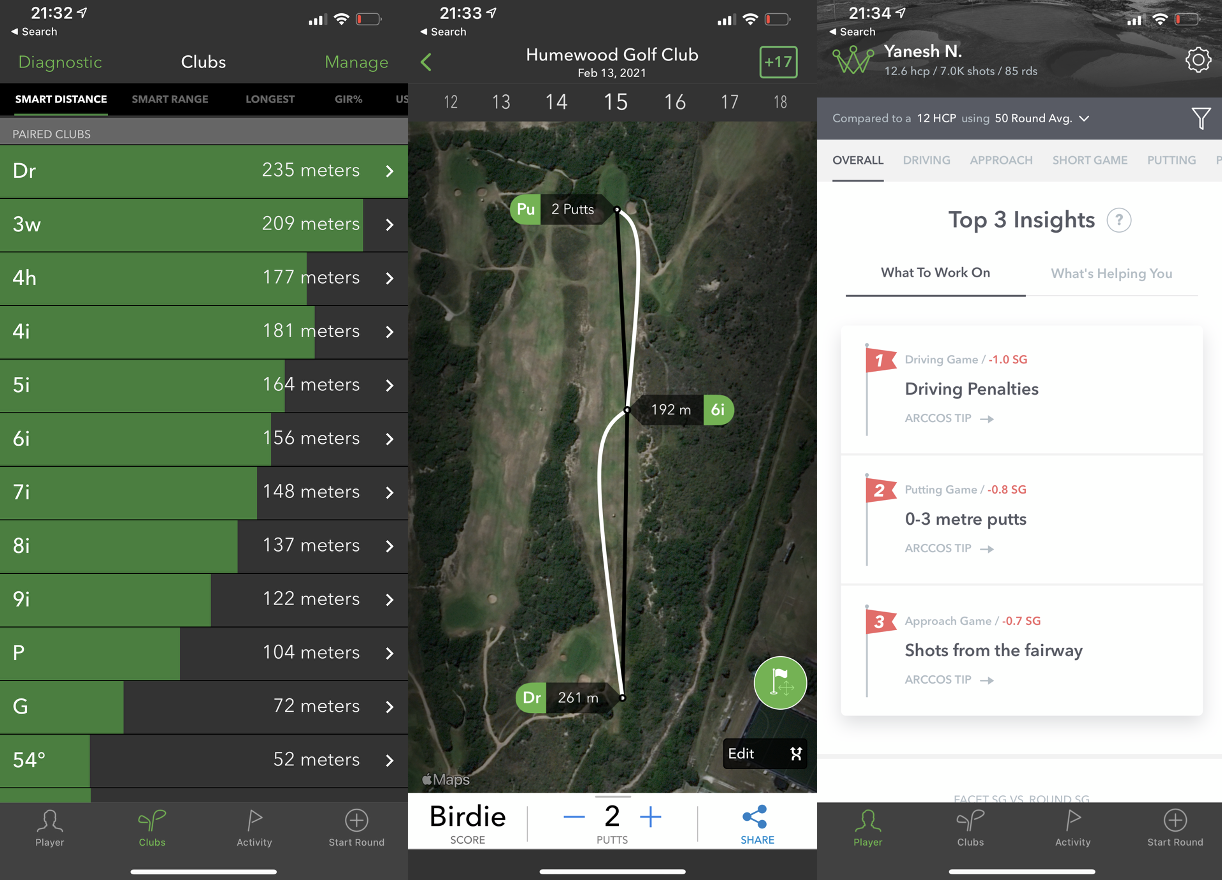

A few years ago, I invested in golf club sensors that captured every swing – recording distance, accuracy, and club performance. Over four years, I built up a huge dataset highlighting exactly where I needed to improve. The technology worked perfectly, but my handicap got worse.

Why? I stopped practising. I didn’t go to the driving range, played less often, and wasn’t acting on the data. The technology showed me what to improve, but I wasn’t willing to put in the effort.

By contrast, another digital investment has had a massive positive impact on my health and well-being.Around the same time, I also purchased a wearable health tracker – a Whoop band that measures my sleep quality, physical and mental strain, and recovery from exercise.

Over time, the insights sparked real behavioural change: I improved my sleep, lost 15 kilograms, and even gave up alcohol to boost recovery scores in a friendly competition with my wife.

This time, the data became a motivator. I acted on the insights, turning these actions into lifestyle changes that had a lasting impact on my health.

Similarly, digital tools can provide incredibly precise insights into factory performance. But just like my golf game, if teams don’t act on those insights, nothing changes. Success comes when digital adoption is treated as a lifestyle change – a permanent shift in daily habits and how the organisation operates – rather than a once-off project.

Here are four common human challenges we have encountered among our manufacturing customers – and the digital tools we developed to help their teams realise the benefits.

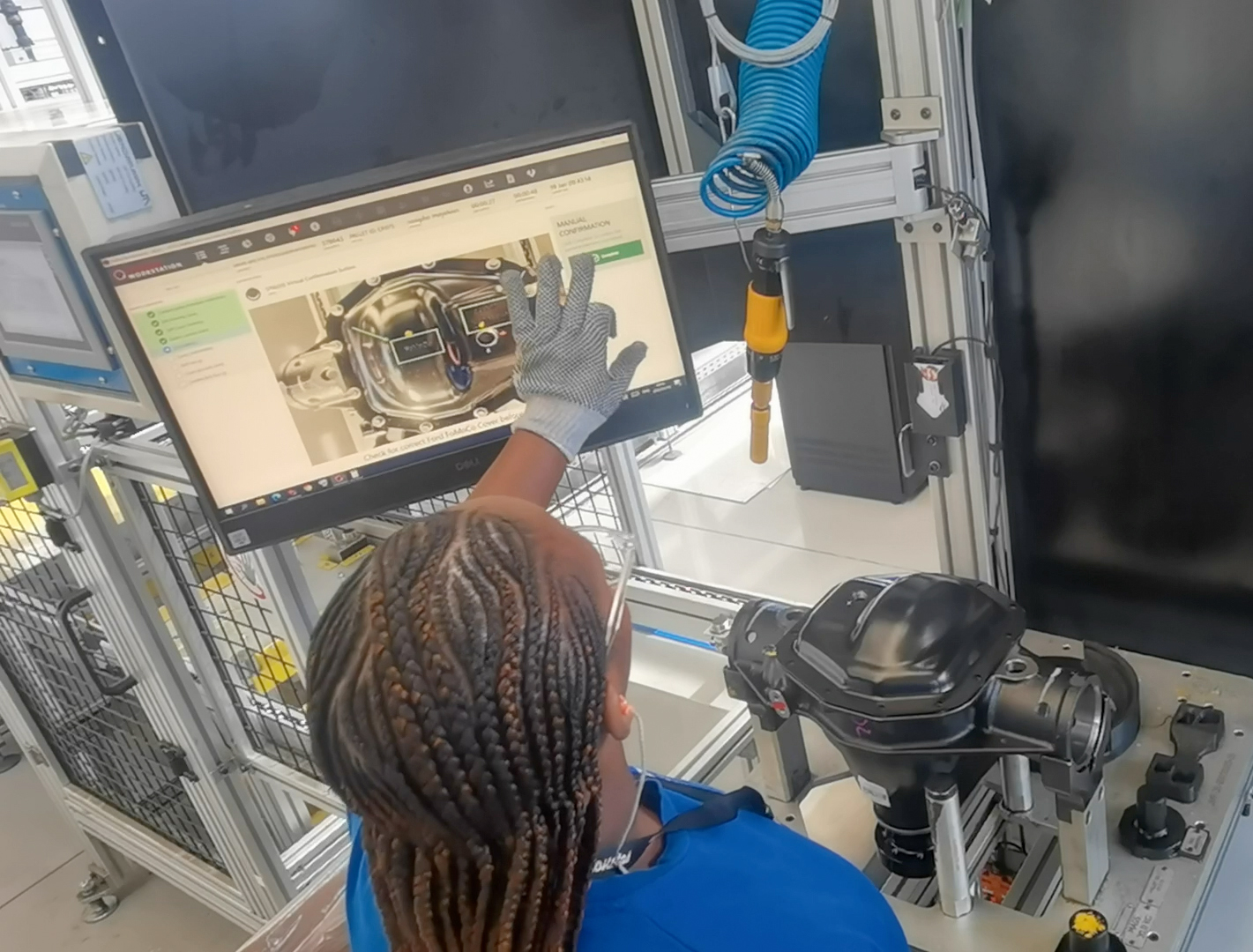

Solution: A smart operator platform that combined:

Results: Reduced training requirements, improved process compliance, and more consistent quality – all without raising the skills barrier for new operators.

Solution: Gamified operator dashboards showing each operator’s live production data, cycle time trends, and improvement areas – similar to my Whoop leader board.

Insights:

Results:Operators began taking ownership. For example, one worker noticed barcode scans slowing her cycle time and asked maintenance to fix a printer three stations away – unprompted. There was a noticeable cultural shift where operators proactively improved their own performance, driving bottom-up continuous improvement.

Solution: Digital task management app enabling clear assignment, tracking, and real-time reporting.

Insights: Initially, middle management resisted the solution because this transparency exposed missed tasks to leadership. The breakthrough moment came when they saw how the live dashboard showing preventative maintenance compliance had dramatically simplified customer audits. Turning a pain point into a quick, positive process ensured their buy-in.

The result: Reduced downtime through clear accountability, a productivity boost without hiring more technicians, and stronger audit readiness.

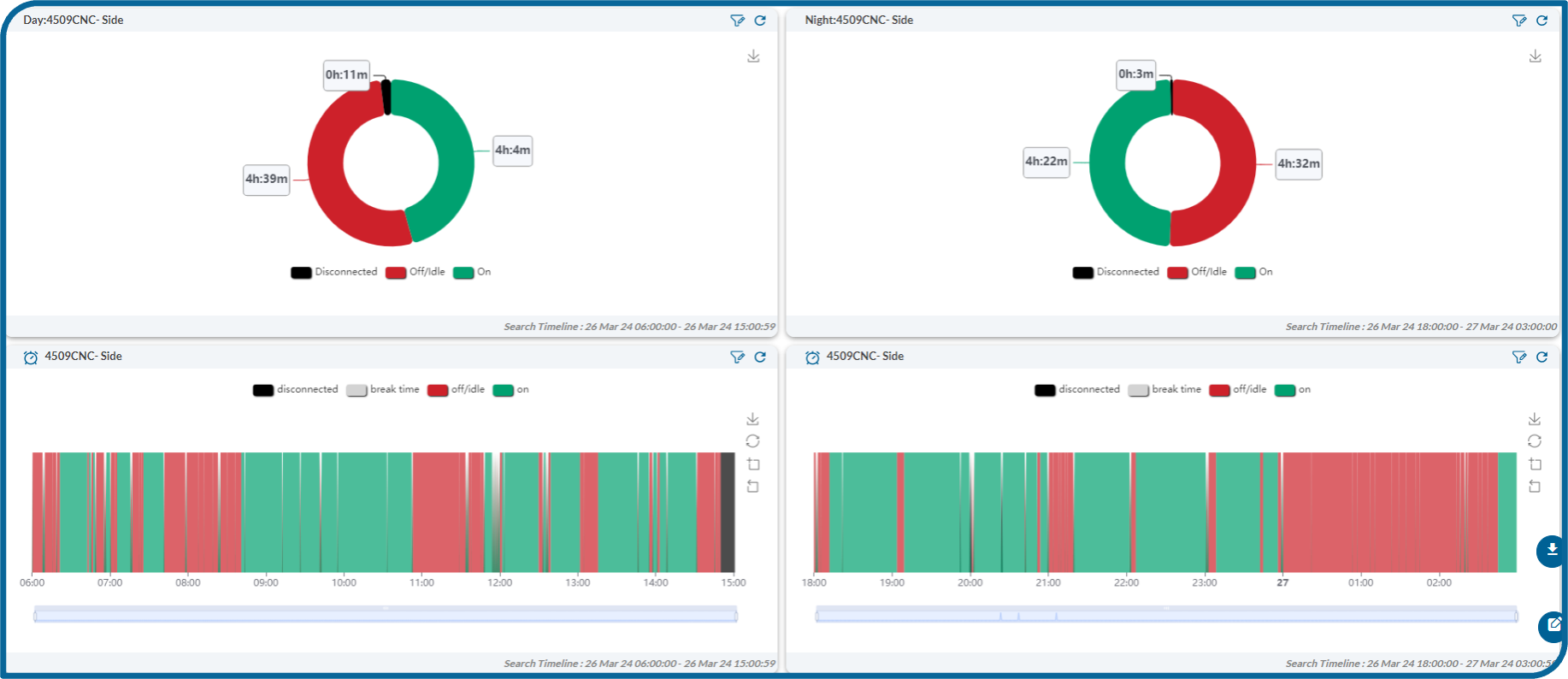

Solution: Vibration sensors to monitor machine utilisation in real time with simple data visualisation on a shop floor screen.

Insights: In one particular instance, the data from CNC machines revealed that night shift changeovers took 3 minutes instead of 30 seconds, and breaks were significantly longer.

The result: Increased visibility saw output improve by 40% in just three weeks – without any process changes.

Here’s how to ensure that real, effective digital transformation happens on your shop floor so that your smart factory can start delivering on its promise and potential:

The most advanced AI or automation system won’t deliver results unless leadership commits to seeing it through in the long term, middle management embraces transparency, and operators are empowered to act on insights. The power still rests in human hands.

Check out our other Resource sections:

Sign up to get the latest thought leadership articles – written by our experts – delivered straight to your inbox.