- Case Study

- Dinex Emission Solutions

Catalytic Converter Assembly Line

Managing high variation in the product mix

How our flexible solutions solved multi-variant production challenges for Dinex

- Improved operator onboarding:

ODIN Workstation provides intuitive, dynamic worker guidance, adapting to the unique variant being built in the station. - Managing 21 variants on the same fixture:

ODIN Workstation manages smarter changeovers, providing operator guidance and correct fixture validation using QR codes. - End-to-end production traceability:

Dinex supplies a printed standard report for all parts to their customer. - Ergonomic material handling:

Throughput improved with the help of easy-to-use tackles and push trolleys. - Complex laser marking on round parts:

6-axis robot traces the same curvature path to achieve repeatable quality.

- JENDAMARK DELIVERED

- Chennai, India

About the Customer

Dinex Emission Solutions India is a subsidiary of the Denmark-based Dinex Group, a global leader in exhaust and emission control systems. Established in 2020, the Indian operation serves the growing demand for advanced emission solutions across the automotive and industrial sectors in India. The Chennai-based facility serves as a vital node in Dinex’s global supply chain, delivering customised solutions that help customers like Tata Motors, Ashok Leyland and Caterpillar meet stringent CPCB and BS-VI emission regulations.

With production volumes increasing and emission regulations tightening, Dinex recognised the need for a technology-driven production ecosystem that ensures high throughput, zero-defect quality, and robust process traceability.

Key Challenges

Before the upgrade, Dinex relied on manual processes for canning and final assembly. Part identification and traceability relied on dot-peen marking, which was slow, inconsistent, and limited in terms of automation and data logging capabilities. A lack of centralised process validation and variant management increased operational complexity.

As the number of part variants surged from eight to 21, managing fixtures, validating part-specific processes, and maintaining production consistency became increasingly difficult. Dinex needed a transformation that could:

- Improve cycle times

- Ensure quality through full digital traceability for every component

- Handle multi-variant production seamlessly

- Enhance operator safety through ergonomic material handling

- Provide variant-specific digital operator guidance

Recognising these challenges, Dinex partnered with Jendamark India to develop and deploy an end-to-end manufacturing system tailored to their requirements.

Our Solution

Jendamark delivered a modular yet fully integrated automation solution combining mechanical design, controls engineering, traceability software, and ergonomic material handling equipment. The project was implemented in a phased manner, ensuring a smooth transition and scalability.

- Solution 1

Assembly line with ODIN Workstation

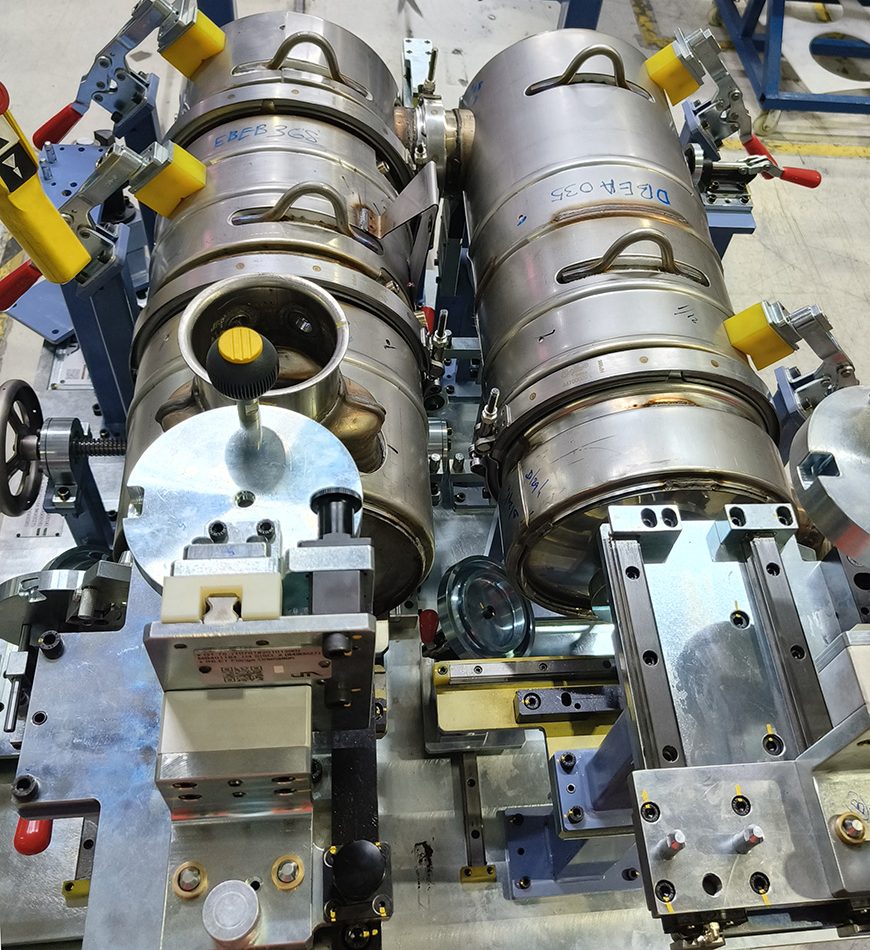

- A custom-designed canning line was developed to support Dinex’s multiple customers and product variants.

- Guided workflows for operators helped standardise operations and reduce errors.

- The initial set-up supported eight variants, with provision for rapid scaling up to 21 variants.

- Real-time data logging, step-by-step process validation, and variant-based instructions were implemented to ensure consistency.

- The system dynamically adjusts processes, machine settings and worker guidance according to the selected part variant.

- Solution 2

End-of-line testing and validation

- A robust leak test station was introduced to ensure product integrity before marking or dispatch.

- The machine automatically validates each part, ensuring that only leak-free assemblies move forward.

- Test data is captured in the ODIN Workstation system and linked to the part serial number for traceability.

- Solution 3

Laser marking station with automation

- Jendamark replaced the legacy dot-peen marking system with a modern fibre-optic laser marking station.

- The station marks QR codes, alphanumeric IDs, and logos with high precision.

- ODIN Workstation enabled automatic parameter adjustment based on variant selection.

- Integration with ODIN Workstation ensures that each mark is correctly linked to the component’s digital record.

- Solution 4

Fixture management and storage optimisation

- A 16-slot fixture storage rack was custom-built to facilitate organised storage of variant-specific fixtures.

- The compact, space-saving design reduces floor clutter and enables quick fixture changeovers.

- Operators can easily identify and retrieve the correct fixture based on visual tags or ODIN Workstation prompts.

- Solution 5

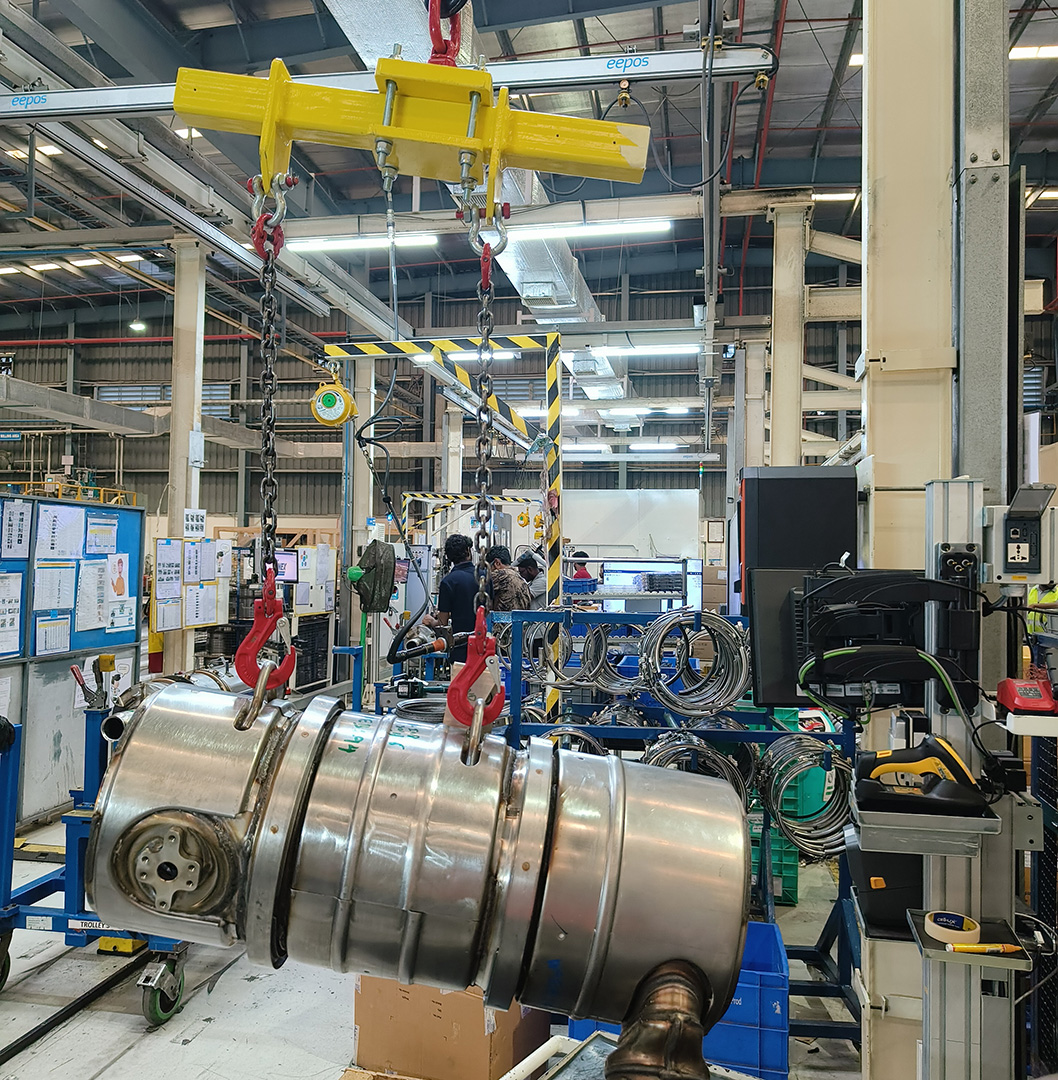

Ergonomic component handling with tackles

- To support safe and efficient loading/unloading, Jendamark provided five tackles.

- These are suspended on a robust EEPOS rail system, allowing operators to glide heavy parts across work zones effortlessly.

- The tackles include electric hoists that minimise physical strain and prevent mishandling.

- The system ensures coverage across multiple stations and provides better mobility, precision, and safety.

- Solution 6

Centralised traceability and control

ODIN Workstation is the backbone of this transformation. It acts as a digital twin of the production floor, capturing, guiding, and validating every step of the assembly process.

Key features include:

- Live dashboards for real-time performance monitoring.

- Digital instructions ensure operators follow the correct steps per variant.

- Automated build reports that include leak test data, marking results, timestamps, and operator IDs.

- Seamless integration with machine PLCs and robotic systems.

- Simplified auditing with complete build history and inspection logs.

By integrating ODIN Workstation with both mechanical and electronic systems, Dinex achieved true process intelligence.

Customer Benefits

Jendamark’s holistic solution has empowered Dinex with a production system that is efficient, intelligent and scalable.

Notable outcomes include:

- Enhanced productivity (50%):

Faster cycle times with stable shift-wise output. - Reduced operational costs(30%):

Manpower saving through automation. - Improved safety:

Electric hoist tackles reduce risk of injury. - Data-driven decisions:

Real-time dashboards enable better production planning. - Zero defect manufacturing:

Integrated validation minimises rework. - Scalable architecture:

Easily accommodates future variant expansion or process upgrades.

Key Takeaways

By combining modern automation with the power of ODIN Workstation operating system, Jendamark helped Dinex Emission Solutions transform from a largely manual legacy system into a digitally enabled, operator-friendly, and future-proof manufacturing environment.

It sets a new standard in smart manufacturing practices and quality assurance for the global emission systems industry.