High-Precision Technologies

Applying the right specialised process to assemble your product is critical to its performance and overall quality.

- CRITICAL ASSEMBLY PROCESSES

Expert Technologies

Jendamark’s assembly systems feature a range of high-precision technologies.

Pressing

Whether you require small or large-scale precision pressing operations, our team delivers reliable, efficient solutions tailored to your specific needs, including monitoring force and displacement, and implementing specialised press force strategies.

Specialised pressing methods include:

- Manual arbour pressing

- Hydraulic pressing

- Servo pressing

- Hydro pneumatic pressing

For a wide range of components:

- Studs

- Tubes

- Bearings

- Pins

- Seals

- Dowels

- Shafts

- Rings

Tightening

Our precision tightening solutions ensure optimal performance and safety, using methods such as:

- Straight

- Torque

- Angle

- Yield tightening

Applications:

- Axle assemblies

Precise bolt tightening using synchronised yield methods - Ring gears

Accurate torque control for secure mounting - Engine mountings

Reliable tightening to prevent vibration and noise - Head and diff covers

Consistent sealing and performance - Ring covers

Secure attachment for critical components - Axle bolts

Consistent and controlled tightening for safety

We also offer pre-torque tightening and automatic tightening solutions to streamline your production processes and improve efficiency.

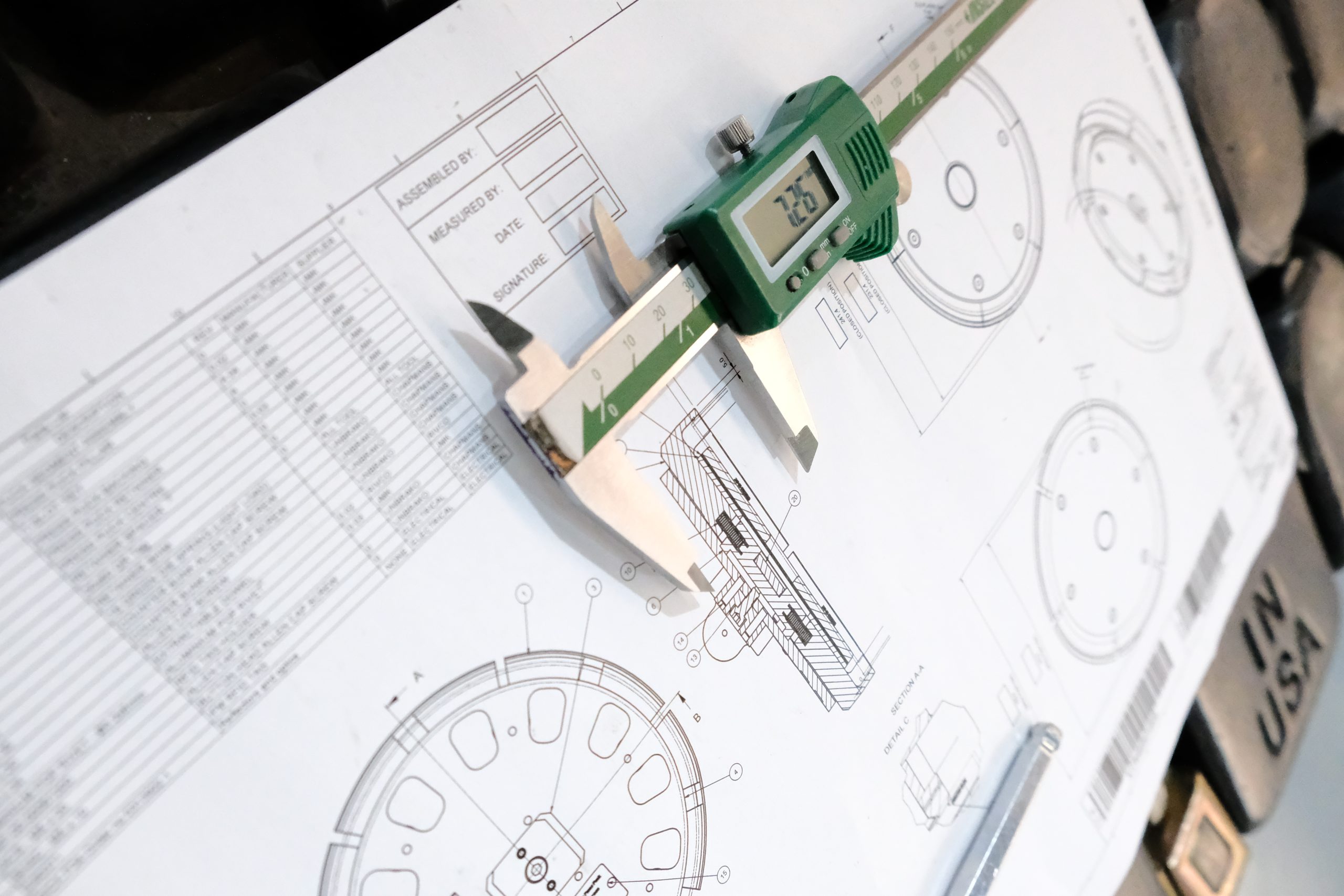

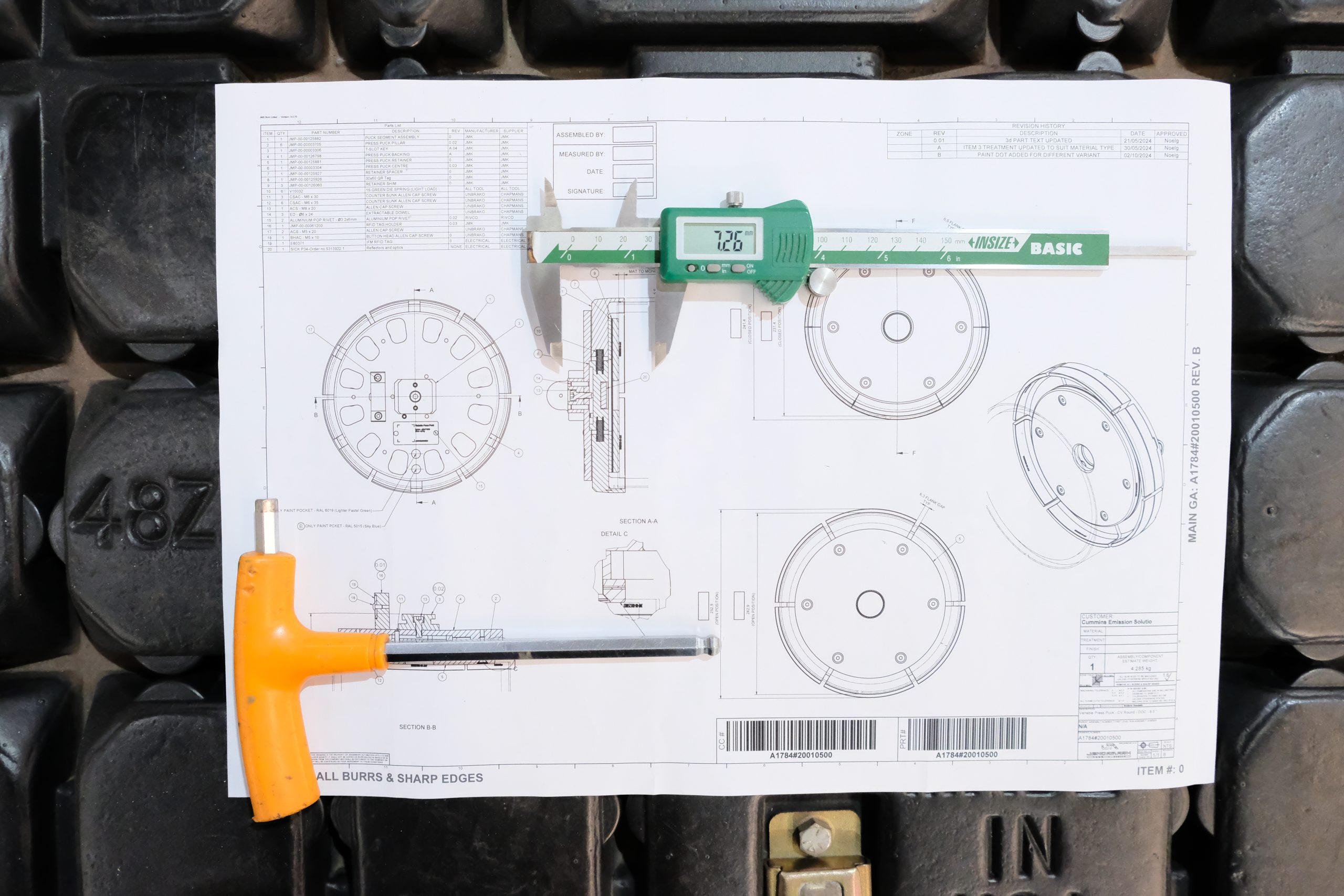

Gauging and measurement

Overview

Overview:

Our advanced gauging and measurement technologies can help you achieve higher levels of quality, efficiency, and productivity in your operations.

Specialised measuring methods include:

- Laser distance measurement

Accurate measurement of distances using laser technology - Laser displacement measurement

Precise measurement of surface displacement or deformation - Non-contact measurement

Measurement without physical contact, ideal for delicate or moving objects - Probe measurement

Contact-based measurement using probes for dimensional accuracy - Vision system measurement

Optical measurement using cameras and image processing for dimensional inspection and analysis

Industries:

- Manufacturing

Quality control, dimensional inspection, and process monitoring - Automotive

Assembly line inspection, component verification, and reverse engineering - Aerospace

Aircraft component inspection, dimensional verification, and tolerance analysis - Electronics

PCB inspection, component placement verification, and assembly line control - Research and development

Prototyping, material testing, and scientific experimentation

Benefits:

- Improved accuracy

Precise measurements for enhanced quality control - Increased efficiency

Faster inspection times and fewer errors - Enhanced productivity

Streamlined production processes and improved yields - Cost savings

Reduced scrap rates and rework costs

By using our precision gauging and runout measurement expertise, you can ensure the accuracy and reliability of your products.

Applications:

- Corner units

Measuring the runout of components on axle lines. - Pinion runout

Assessing the concentricity of a pinion gear. - Flange runout

Measuring the deviation of a flange face from a true plane. - Shaft runout

Evaluating the straightness and concentricity of a shaft.

Backlash Measurement

Backlash refers to the amount of play or clearance between two meshing gears or other moving parts. Accurate backlash measurement is crucial for ensuring proper operation, efficiency, and longevity of mechanical systems.

Why backlash measurement is important:

- Precision

Ensures that components fit together correctly and operate smoothly. - Efficiency

Reduces noise, vibration, and energy loss. - Durability

Prevents excessive wear and tear on moving parts.

Our specialised techniques include:

- 3-point measurement

This method involves measuring the backlash at three points along the gear mesh to obtain an average value. - Manual audit

A more traditional approach where backlash is measured manually using tools like feeler gauges or dial indicators. - Dynamic backlash measuring

This technique uses advanced equipment to measure backlash while the system is in motion, providing real-time data on clearance variations.

Applications:

- Automotive

Gearboxes, differentials, steering systems - Industrial machinery

Gear drives, gearboxes, machine tools - Aerospace

Aircraft components, landing gear - Robotics

Robotic arms, joint mechanisms

Gear Friction Measurement

Our expertise lies in measuring gear friction using specialised tools and techniques. By precisely measuring gear friction and applying appropriate torque, we help ensure the efficiency and reliability of your gear-driven components.

Services offered:

- Torque measurement

Accurately measure the torque required to rotate gears. - Pinion nut tightening

Apply the correct torque to securely tighten pinion nuts. - Preload application

We understand the impact of preload on torque and ensure optimal performance.

Applications:

- Differential assemblies

- Gearboxes

- Other gear-based systems

Torque To Turn

Gear friction and torque measurement is a critical aspect for ensuring optimal performance, efficiency, reliability and longevity in mechanical systems.

Our specialised techniques include:

- Torque to rotate

Measuring the torque required to rotate a gear or gear pair. - Pinion nut tightening

Assessing the torque applied to tighten the pinion nut, which affects gear meshing and performance. - Spinning and measuring torque

Determining the torque generated during gear rotation, providing insights into friction and efficiency.

Why is gear friction measurement important?

- Efficiency

Reduces energy loss and improves overall system performance. - Durability

Prevents excessive wear and tear on gear components. - Noise reduction

Minimises noise and vibration caused by friction. - Optimisation

Enables fine-tuning of gear design and operation.

Applications:

- Automotive

Gearboxes, differentials, steering systems - Industrial machinery

Gear drives, gearboxes, machine tools - Aerospace

Aircraft components, landing gear - Robotics

Robotic arms, joint mechanisms

Leak testing

We specialise in a variety of leak testing methods, including pressure decay tests.

Applications:

- Housing components

- End-of-line assemblies

- Post-welding inspection

- Weld integrity verification

- Component sealing checks

- Flaw detection

- Sample testing

Robotic sealant application

We specialise in robotic sealant applications, including :

- Dosing systems

- Glue dispensing

- Glue spraying

- Electric module sealing

- Gasket sealing for components like differentials and engine lines

Our robotic sealing capabilities cover a wide range of applications, such as spot sealing, bead sealing, structural sealing, and cosmetic sealing.

Process planning

We specialise in process planning, a critical aspect of manufacturing that involves analysing and optimising production processes. By leveraging our process planning expertise, you can streamline your production, reduce costs, and improve overall efficiency.

Our expertise includes:

- Cycle time optimisation

Reducing the time required to complete a process. - Bottleneck reduction

Identifying and addressing constraints that slow down production. - Line balancing

Ensuring a smooth flow of work through the production line. - Operator efficiency optimisation

Improving the productivity and effectiveness of your workforce. - Layout optimisation

Arranging equipment and workstations for maximum efficiency. - Cycle time calculation and assessment

Analysing and evaluating process times.

Traceability solutions

Our traceability solutions leverage advanced technologies like laser scanning, direct part marking, and barcode scanning to link data directly to components. This ensures complete traceability throughout the product lifecycle, allowing you to gain valuable insights into your operations, improve product quality, and meet regulatory requirements.

- Laser scanning

High-precision scanning for detailed component inspection and tracking. - Direct part marking

Permanent marking of part information directly onto the component. - Scanning

Efficiently capturing and storing data from barcodes, QR codes, and other markers. - Barcoding

Implementing barcode systems for easy identification and tracking. - Pin stamping

Applying permanent marks or identification numbers using pin stamping techniques. - Linking data to components

Connecting component data to relevant information, such as manufacturing records, quality control results, and maintenance history.

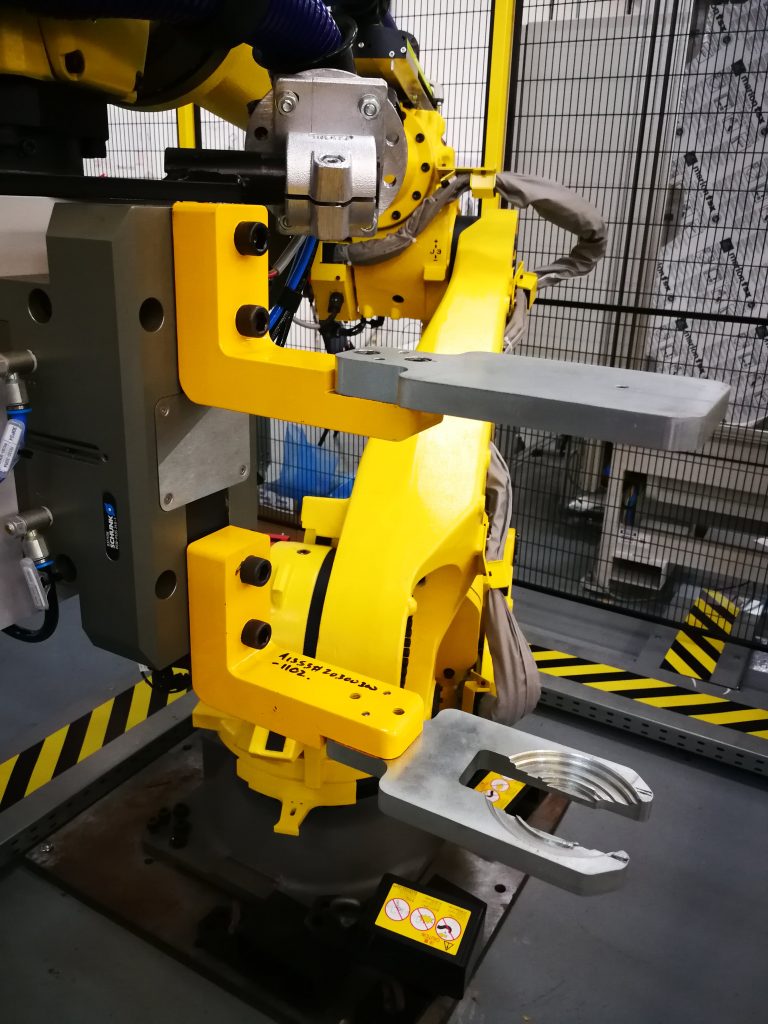

Auto and manual part handling

We specialise in a variety of part handling technologies, including:

- Grippers

- Manipulators

- Robots

- Gantry systems

- Lift assist devices

Applications:

- Assembly lines

Moving components from one station to another. - Material handling

Transporting raw materials, finished products, and work-in-progress. - Machine tending

Loading and unloading parts from machines. - Quality inspection

Handling parts for inspection and testing. - Welding and assembly

Holding and positioning parts for welding and assembly processes. - Packaging

Packaging finished products for shipment.

Build your next line with us

Contact us for component manufacturing and automation solutions. The future starts today.