Logic dictates that to make more, you need more – more machines, operators, and shifts, right?

When demand rises, expansion feels like progress. But in practice, this approach often leads to inefficiency, unnecessary complexity, and wasted capital. Most factories already possess untapped capacity. The challenge lies in finding and unlocking it.

Traditionally, scaling production relies on senior managers’ gut feel and experience. But educated guesses can end up being costly on a number of fronts:

This is what many in the industry now call the scaling trap: the false belief that growth must come from expansion. What actually drives sustainable growth is knowing where and how to expand, guided by data, not assumptions.

Studies across hundreds of assembly lines worldwide consistently reveal the same truth: between 20% and 40% of potential output is quietly lost to small inefficiencies. Variable operator performance, paper-based processes, and disconnected systems all chip away at productivity and output.

Because data is often scattered across systems or trapped on bits of paper, managers can’t see the trends and home in on areas where time, materials, or effort is being wasted. The key to scaling smarter is data visibility. You can’t improve what you can’t measure.

The most progressive manufacturers have started approaching scaling as a data-driven discipline. Rather than asking, “What do we need to buy?”, they ask, “What can we unlock with what we already have?”

This approach follows five basic principles:

Instead of throwing more resources at the problem, let the data lead and show you where to act – and where not to.

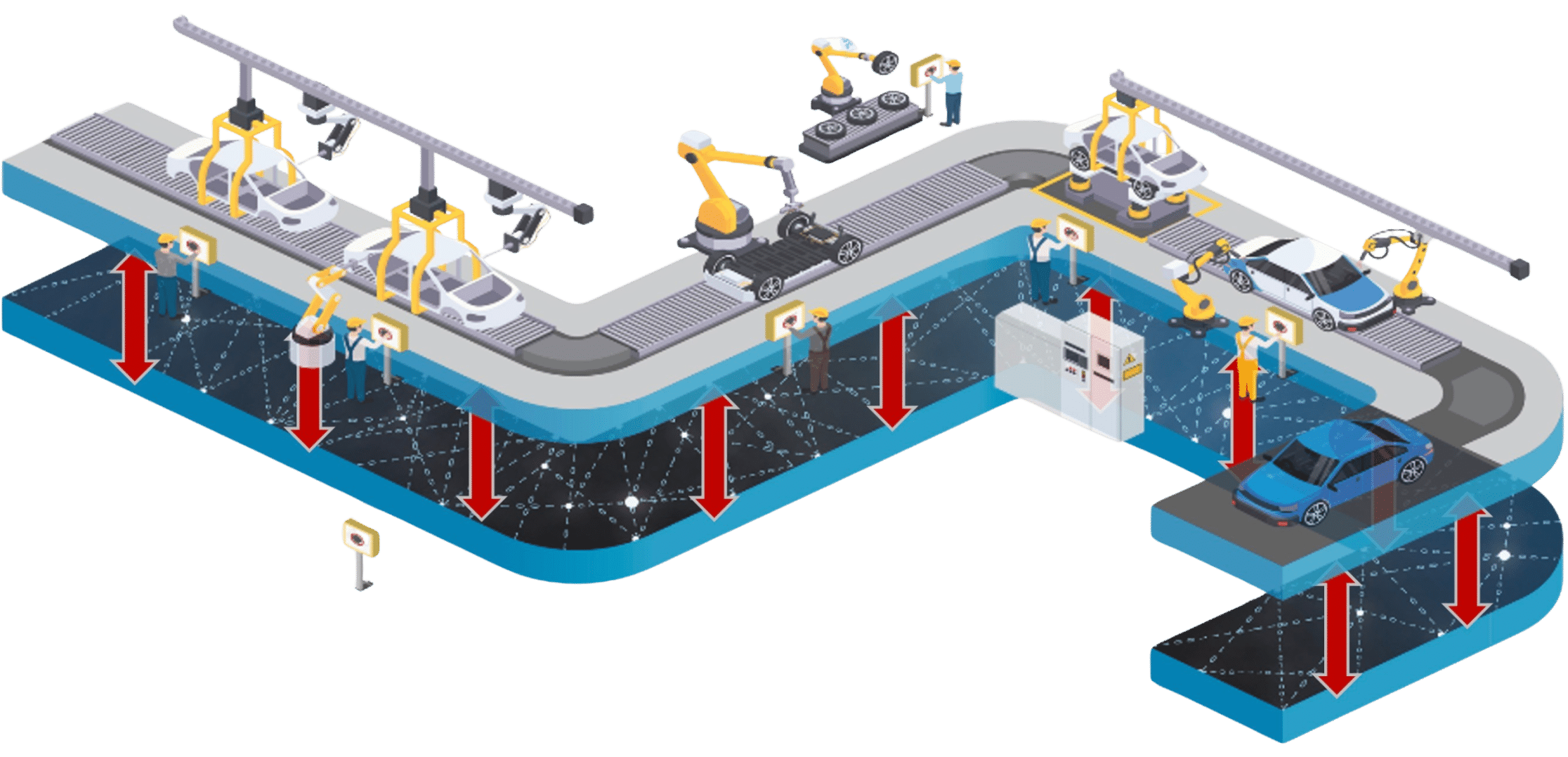

Disconnected systems are another invisible drag on efficiency. Every manufacturer pays a ‘fragmentation tax’ – the lost time, integration headaches, and extra costs that come from juggling multiple tools and vendors that don’t talk to one another.

Unifying people, processes, and machines on a single data backbone simplifies management and magnifies performance. When configuration, execution, and validation happen in one digital environment, change just happens faster.

Once manufacturers capture reliable data, they can start to see the hidden story behind the line.

These insights allow decision-makers to target their investments precisely. When a new machine or operator is added, it’s at the point where data proves it will deliver the greatest return, which means you can invest and scale with confidence.

Investing in an operator guidance system is one of the expenses that requires due consideration – and it can cut training and other labour-related costs.

When operators receive clear, dynamic guidance, their stress levels drop, confidence rises, and quality improves. As a result, senior staff can also be freed from repetitive training to focus on innovation and problem-solving.

Globally, a shortage of skilled labour means that empowering and retaining your existing workforce is as important as optimising your machines. The best-performing factories don’t just focus on equipment efficiencies – they’re also inclusive, and people-centred.

Smart scaling is a continuous cycle: digitise, diagnose, optimise, and scale. Each cycle compounds the results, so that everyday operations become an improvement-driven routine. This is what moves your manufacturing from reactive mode to resilience.

The next level of manufacturing growth won’t be achieved by those who add the most machines or operators, but by those who extract the most value from the ones they already have.

By combining real-time visibility, process standardisation, and empowered people, manufacturers can scale production intelligently – achieving higher output, stronger quality, and better margins without adding a single headcount or square metre of floor space.

To learn more about this, download your FREE Smart Scaling Playbook – and see how data-driven assembly lines use Jendamark’s assembly line operating system, ODIN Workstation, to increase output, reduce training time, and make informed decisions that protect profitability.

Check out our other Resource sections:

Sign up to get the latest thought leadership articles – written by our experts – delivered straight to your inbox.