EV-Specific Capabilities

- AREAS OF EXPERTISE

EV Technologies

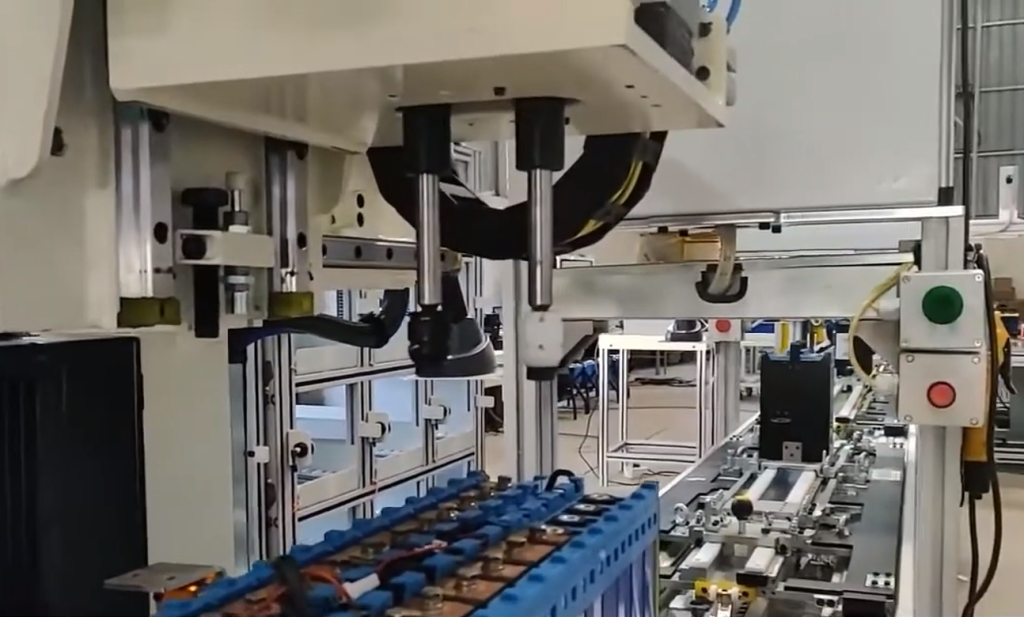

Jendamark’s assembly systems feature a range of industry-leading technologies, and we specialise in these high-precision solutions.

Polarity checking

Polarity checking ensures that the electrical connections (positive and negative terminals) are correctly aligned or arranged when assembling a battery pack. It verifies that the cells and the overall pack are connected in such a way that the current flows in the correct direction.

Purpose:

- Prevent reverse polarity, which can cause short circuits, inefficiency, or damage to battery cells.

- Ensure the correct assembly of the battery pack for functionality and safety.

- Avoid misconnection issues that could potentially lead to fires, overheating, or equipment failure.

Benefits:

- Safety: Correct polarity ensures that the battery pack will function safely and efficiently. Reverse polarity could cause short circuits, damage, or even thermal runaway.

- Reliability: Verifying polarity prevents the risk of electrical issues, ensuring the pack performs as intended in its application.

- Longer lifespan: Proper polarity prevents premature wear or failure of battery cells or the pack due to incorrect connections.

Technology used:

- Automated testing systems: These systems are equipped with voltage measurement devices or continuity testers. They scan the entire battery pack for proper polarity and alert operators to any misalignment.

- Advanced vision systems: Systems with AI can be programmed to visually inspect the orientation of cells, tabs, and connectors in a battery pack. These systems can quickly verify that the correct polarity is established.

Laser Tab Welding

Laser tab welding is a process used to create precise and strong electrical connections between the battery cells and the interconnecting tabs (usually made of nickel or other conductive metals). This method uses focused laser energy to melt and join the metal tabs to the battery cell terminals, ensuring a high-quality, low-resistance connection.

Purpose:

- Efficient and precise welding: Ensures a strong, high-quality weld between the battery cell and connecting tab.

- Reduced risk of damage: Laser welding is a non-contact, localised heat method that minimises the risk of damaging sensitive battery cells during the welding process.

- Consistent and repeatable results: Laser welding ensures uniformity in the welds, which is critical for the performance, reliability, and safety of the battery pack

Benefits:

- High precision: The accuracy ensures that the welds are consistently strong and well-formed.

- Reduced thermal damage: Unlike traditional welding methods, laser welding has a small heat-affected zone, which reduces the risk of thermal damage to the battery cells and other components.

- Minimal material distortion: The localised heat generated by the laser minimises material distortion, preserving the integrity of the cell and the tab.

- Strong, reliable joints: Laser welding creates strong, low-resistance joints that are capable of handling the high currents often required in battery packs.

- Non-contact process: Laser welding is a non-contact process, meaning there is less mechanical stress on the materials, leading to more reliable welds.

- Speed and automation: Laser welding can be automated for high-speed production, leading to faster manufacturing cycles and reduced labour costs.

Technology used:

- Fibre laser welding systems: These are commonly used for high precision, as they deliver concentrated, high-power laser beams. Fibre lasers are known for their efficiency and reliability in welding thin materials like the metal tabs.

- CO2 lasers: Older but still effective, CO2 lasers can also be used in tab welding, though fibre lasers are more common for modern battery production lines.

- Robotic welding arms: Automated robotic arms equipped with lasers move the laser precisely and repeatedly over the weld points. These robots can be programmed for consistent, high-accuracy welding across multiple cells.

- Vision systems: Integrated vision systems may be used to align the tab and cell terminal accurately before welding. They ensure that the laser hits the correct welding location each time, improving consistency.

High potential (hipot) testing

High potential (hipot) testing is an electrical safety test used to verify the insulation integrity of a battery pack. It involves applying a high-voltage potential (much higher than the normal operating voltage) between the battery’s internal components and the ground (or casing) to ensure there are no electrical leaks or insulation failures.

Purpose:

- Safety assurance: To ensure the battery pack’s insulation can withstand higher voltages than it would normally encounter in operation, preventing electric shocks, fires, or other safety hazards.

- Insulation integrity: To ensure no unintended electrical paths or connections (leakage current) exist that could lead to failures.

- Compliance with standards: To meet international safety standards such as IEC 61010, UL, or ISO that require testing for electrical insulation and safety.

Benefits:

- Safety assurance: The primary benefit is ensuring that the battery pack is safe for use by preventing electrical shocks, short circuits, or fires that could result from insulation failures.

- Quality control: Helps identify faulty insulation in battery packs that could lead to early failure in real-world use, thereby improving the overall product quality.

- Regulatory compliance: Helps manufacturers meet regulatory safety requirements, ensuring the product adheres to industry standards and avoiding potential legal and financial consequences from unsafe products.

- Reliability: Increases the reliability and longevity of the battery pack by ensuring its insulation can withstand potential voltage surges and environmental stress.

Technology used:

- Hipot tester: Modern testers can provide precise readings of leakage current and display results in real-time, sometimes with advanced features like data logging.

- Automated test systems: Can integrate hipot testing into the production line, allowing multiple packs to be tested in succession with minimal human intervention. This is ideal for high-volume production environments.

Open-circuit voltage and internal resistance testing

Open-circuit voltage (OCV) testing measures the voltage of a battery or battery pack when it is not connected to any load application.

Purpose:

- Cell sorting: Based on the OCV and IR data, cells can be sorted into different grades.

- Confirm correct cell configuration: To ensure that the cells in the battery pack are of the same grade or type.

- Safety check: To detect any significant issues such as undercharged cells or manufacturing defects that could lead to failure during operation.

Benefits:

- Performance validation: Helps confirm that the battery can provide the necessary voltage when it is placed in service, minimising the risk of performance issues later.

- Early fault detection: Identifies faulty or undercharged cells or other issues in the early stages of production, allowing for corrective actions before the battery reaches the consumer.

- Consistency: Helps ensure that all battery packs are within the required voltage specifications, ensuring consistency across production batches.

- Safety: Prevents potential issues caused by faulty or mismatched cell voltages that could lead to overheating, malfunction, or safety hazards.

- Consistency: Helps ensure that all battery packs are within the required voltage specifications, ensuring consistency across production batches.

- Safety: Prevents potential issues caused by faulty or mismatched cell voltages that could lead to overheating, malfunction, or safety hazards.

Technology used:

- Digital multimeters or voltmeters: High-precision multimeters are necessary for highly accurate measurements, particularly in high-precision applications such as electric vehicles or medical devices.

- Automated testing systems: Equipment integrated into the assembly line can measure the OCV for large batches of battery packs efficiently. The automated system can compare the OCV against the expected value and flag any discrepancies for further inspection.

- Data logging systems: In some production lines, data logging systems are used to track OCV measurements over time. This ensures that the voltage readings are recorded for quality control and traceability purposes.

- Thermal management systems: If the battery pack has been recently charged or discharged, some packs may require a short resting period to allow the voltage to stabilise. In such cases, cooling or thermal management systems can be used to bring the battery pack to a safe testing temperature.

Build high-quality EV components

See how our expert EV technologies help to deliver industry-leading electric vehicle component assembly solutions.