FEATURED

Case Studies

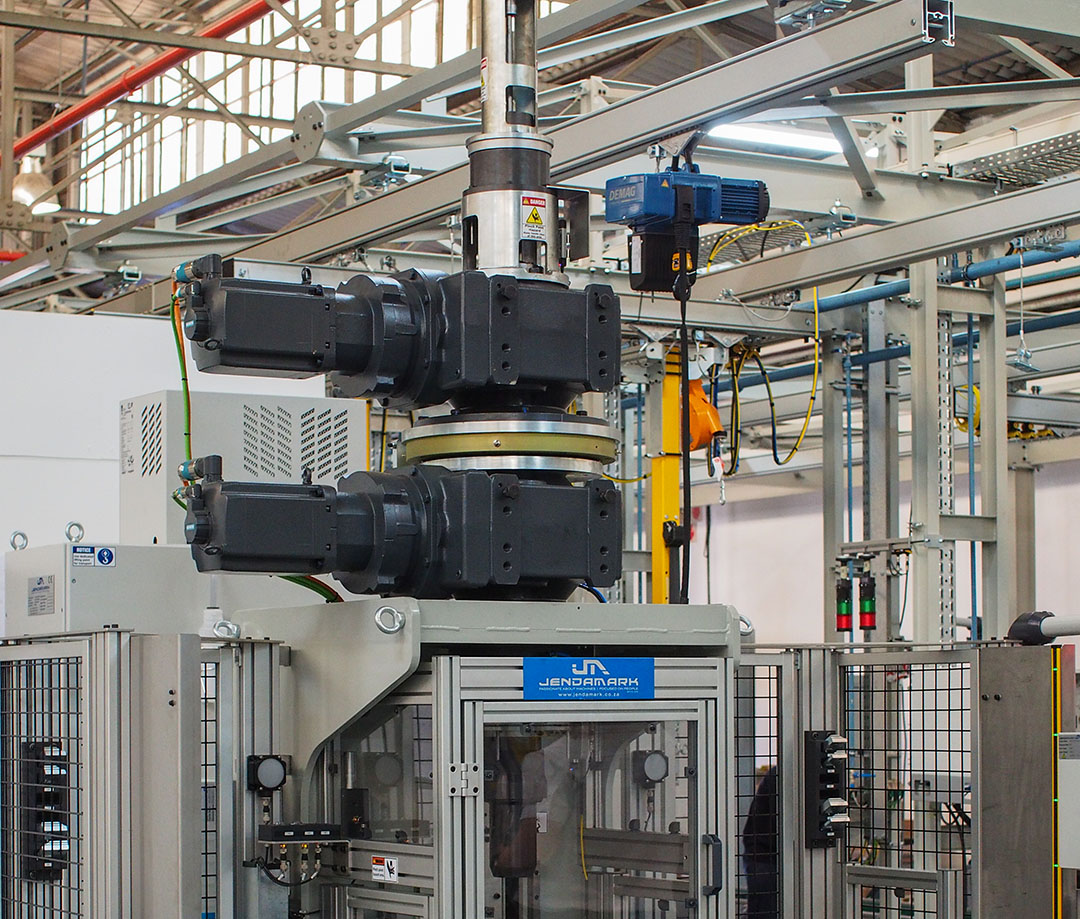

We have designed and manufactured over 3,500 assembly systems for global Original Equipment Manufacturers (OEMs) and their Tier 1 suppliers.

Here are a few of our case studies from around the world.

Newsletter Signup

Jendamark worked closely with Faurecia to develop a set of building blocks for its canning lines globally, and each machine was designed, verified and tested with the customer. Therefore, we knew that...

Part of the Tata Group, Tata Motors is a leading global automobile manufacturer of cars, utility vehicles, pickups, trucks and buses...

Established in 2003, Erkunt Tractor is one of the largest tractor brands in Turkey. Renowned for their high performance and low fuel consumption, Erkunt tractors...

ZF is a global technology company that specialises in mobility solutions for various sectors, including automotive and industrial technology...

German automotive manufacturer Audi had their key European base of operations for engine assemblies in Gyor, Hungary, but saw the opportunity to localise engine assemblies in India at the Skoda plant in Aurangabad...

The ZF Lemförder SA plant in Rosslyn, South Africa, is a well-established automotive supplier that manufactures axle sets for BMW 3 Series vehicles, including the E46, E90, and F30 series...