- Case Study

- Audi

Engine Assembly Line

Digitising the manual assembly of engines

How digitising the manual assembly of engines for Audi improved quality and increased production output by 200%

- JENDAMARK DELIVERED

- Aurangabad, India

About the Customer

German automotive manufacturer Audi had their key European base of operations for engine assemblies in Gyor, Hungary, but saw the opportunity to localise engine assemblies in India at the Skoda plant in Aurangabad. Most automotive assemblies are fairly complex, but an engine is one of the most complex. This is due to the critical components required to ensure the effective and safe operation of the engines being built.

At the Aurangabad plant, the manual assembly steps needed to comply with the predefined, standardised assembly sequences that had been set as the benchmark at Audi’s other locations.

Key Challenges

Audi needed to localise the manufacture of many of their engines in India to take advantage of favourable import duties and incentive programmes introduced by the government of India.

- Challenge 1

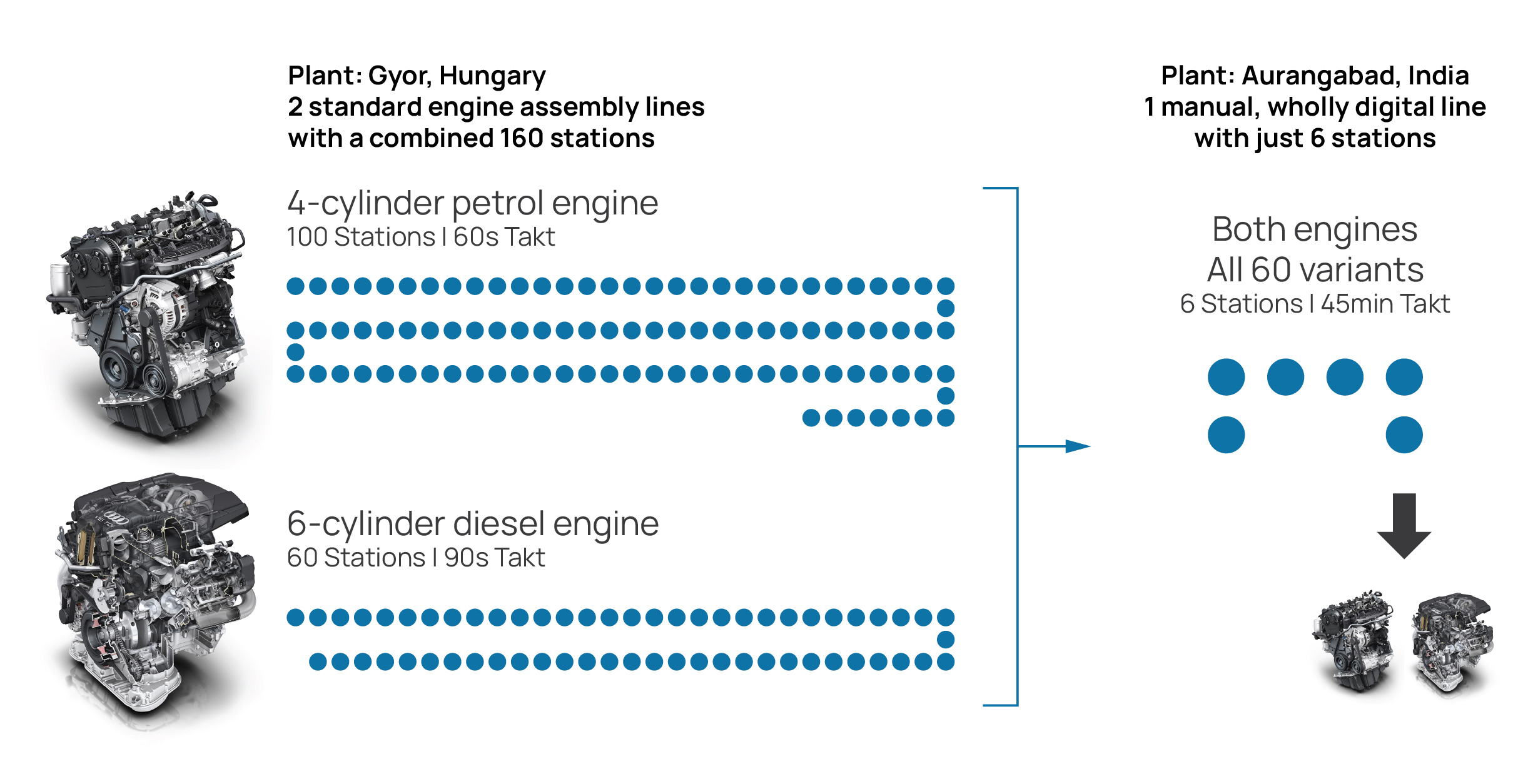

The two main engine categories to be localised were a 2-litre petrol engine and 6-cylinder diesel engine, each with multiple variants that needed to be built on a fully manual production line, with just 6 stations and a much slower cycle time.

- Challenge 2

At the plant in Hungary, quality-critical processes were typically automated. The line had many stations and a cycle time of 60 seconds. Now, with a Takt time of 45 minutes, operators in Aurangabad have hundreds of complex assembly steps to carry out across the four- and six-cylinder variants and sub-variants. With small differences between variants, how to ensure that the operator picks the right gasket, for example?

- Challenge 3

With production required to double after two years, the number of operators per station also doubled. This added complexity, as the available equipment did not change. The problem: How to optimise the synergy between the two operators in a station and ensure that they do not both have a task that simultaneously requires the use of a shared bolting tool?

Our Solution

Solution 1 – Operator guidance system:

While manual engine assembly seems simple from a mechanical perspective, the control system required to ensure that operators are building the right product in the right sequence to the correct standard is complex and challenging. We therefore implemented our ODIN Workstation solution, which includes guided assembly instructions for each variant.

Solution 2 – Quality control:

With our assembly line operating system, every operation has a quality check to ensure that it was done correctly, whether the operator pushes a button to confirm, scans a barcode or takes a measurement, which is then validated. For multi-variant production, ODIN Workstation offers the flexibility for process engineers to define each process, create visual instructions and quality checks, and assign a device to that process, without hard coding.

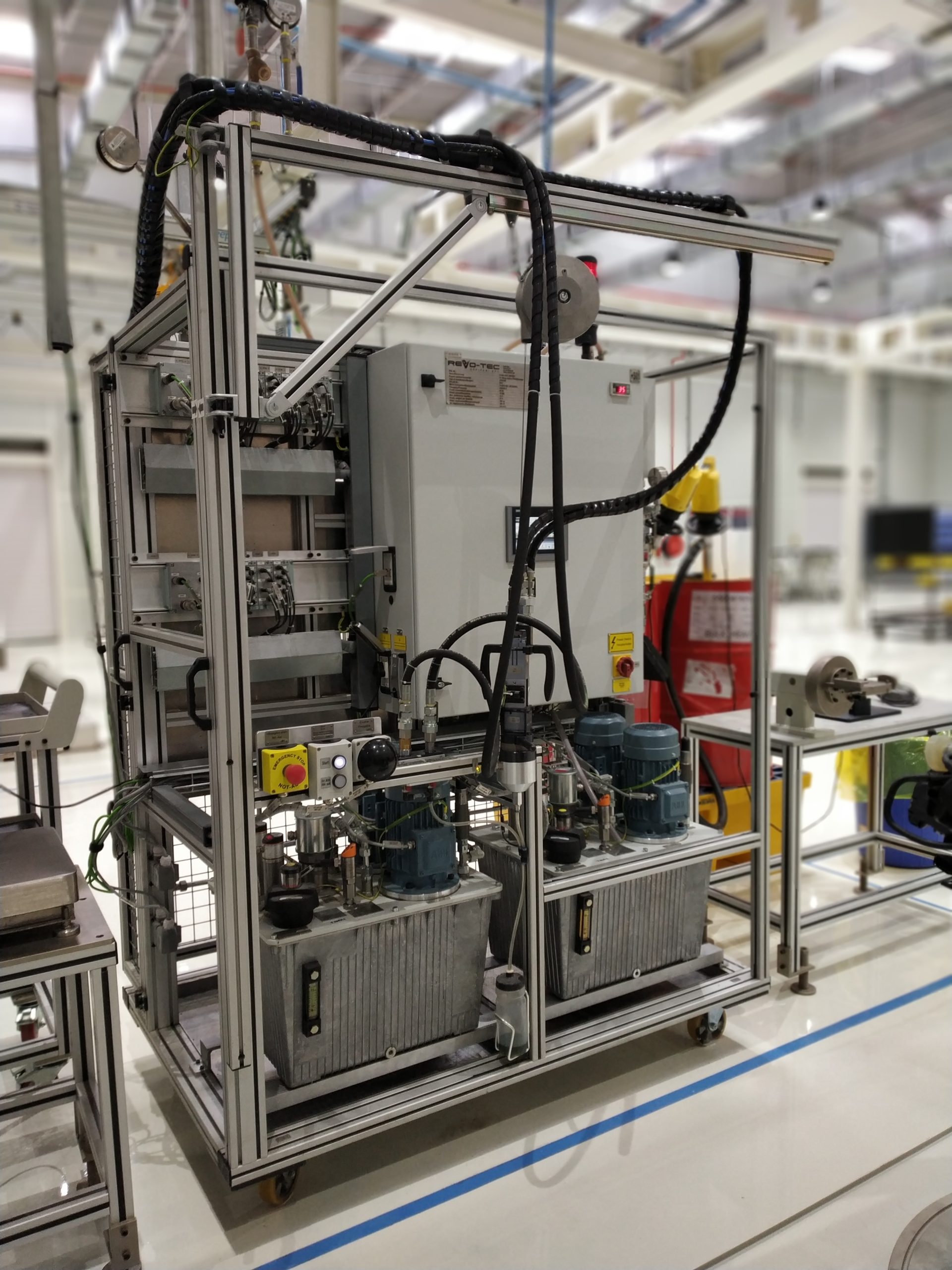

Solution 3 – Device arbitration:

When a second operator was introduced to a station, the process engineer could assign priorities to the operations and equipment, so that the system would not assign an operation if the device involved was already in use by the other operator. This allowed the customer to double the output without buying additional equipment. With many pieces of equipment and up to 9 bolting tools per station, efficient use and sharing of tools was a priority.

Customer Benefits

- New operators are onboarded quicker.

- Process security for each step results in improved quality.

- Worker guidance ensures process compliance.

- Integrated rework function reduces scrap, saving costs.

- Flexibility in process updates and additions saves significant time and cost when changing or adding new engine variants.

- Increased production output with reduced Takt time.

Integrated Rework Strategy

An important feature of Jendamark’s system is the integrated rework strategy. Each manual trolley has an RFID tag, which allows the customer to track the trolley (carrying the engine part being assembled) in the station. If the operator pushes the trolley to the wrong station, the station does not enable and allow work to continue.

If an operation fails in a particular station, the process engineer can set up the process to continue the build until the last station, where it would be flagged to go into the rework area. There the engine would be scanned in, and the system would show exactly what had failed, and provide instructions on either how to fix it or to disassemble it to a point.

If the disassembly option is selected, the engine is reintroduced onto the line and only the operations that were disassembled (as confirmed by the rework station) redone. End-of-line testing equipment can be used to check that the reworked engine now meets the required standards, and a barcode sticker printed to confirm that it has passed the final quality check.