- Case Study

- Erkunt

Engine Assembly Line

Error-proofing tractor engine assembly

How we helped Erkunt localise and error-proof tractor engine assembly in Turkey

- JENDAMARK DELIVERED

- Ankara, Turkey

About the Customer

Established in 2003, Erkunt Tractor is one of the largest tractor brands in Turkey. Renowned for their high performance and low fuel consumption, Erkunt tractors have earned the trust of Turkish farmers and are exported across Europe, North America, Africa, Asia and the Middle East.

In 2017, Erkunt Tractor was acquired by Mahindra & Mahindra. Importing engines from Mahindra’s plant in Nagpur, India, was prohibitively expensive, so there was a need for local manufacturing, while maintaining high quality standards.

In 2022, Mahindra offered Erkunt Tractor the opportunity to work with Jendamark India to develop and commission an Industry 4.0-enabled engine assembly line at their Ankara plant.

Key Challenges

This project represented unknown territory for Erkunt, as it was the first time that the customer would be manufacturing its tractor engines in Turkey. Jendamark India was tasked with the design, development and implementation of the manual assembly line.

- Challenge 1 – Process security:

Erkunt wanted to avoid some of the common process security and product quality challenges associated with manual engine assembly.

- Challenge 2 – Operator training:

Operators needed to be upskilled quickly to handle the new assembly process without a massive training burden.

- Challenge 3 – Data traceability:

Previously, when errors occurred, a lot of time was lost to root cause analysis, as there was little control of manual processes or associated data traceability.

Customer Requirements

Customer goals for the line included:

- Cost benefit and easy to set up

- Zero-error assembly process

- Improved process security and quality

- Cycle times needed to be achieved

- Digitalised assembly data for every part

Customer Benefits

- Increased operator efficiency

- Enhanced assembly process security

- Delivered overall quality product

Our Solution

Jendamark introduced our data-driven digital production solution – ODIN Workstation.

Solution 1 – Operator guidance system:

Presenting step-by-step work instructions in Turkish, with supporting visuals, makes the process easy for new operators to understand and follow efficiently and accurately, reducing on-the-job training time.

Solution 2 – Process security:

To ensure process security, operators must complete all operations, including any measurement or testing, in the correct sequence. The system does not allow the operator to proceed if a step or station has been skipped.

Solution 3 – Quality assurance:

Every step in the assembly process is recorded, traced and reported on. The solution connects process data with quality assurance data for end-of-line or pre-dispatch inspection.

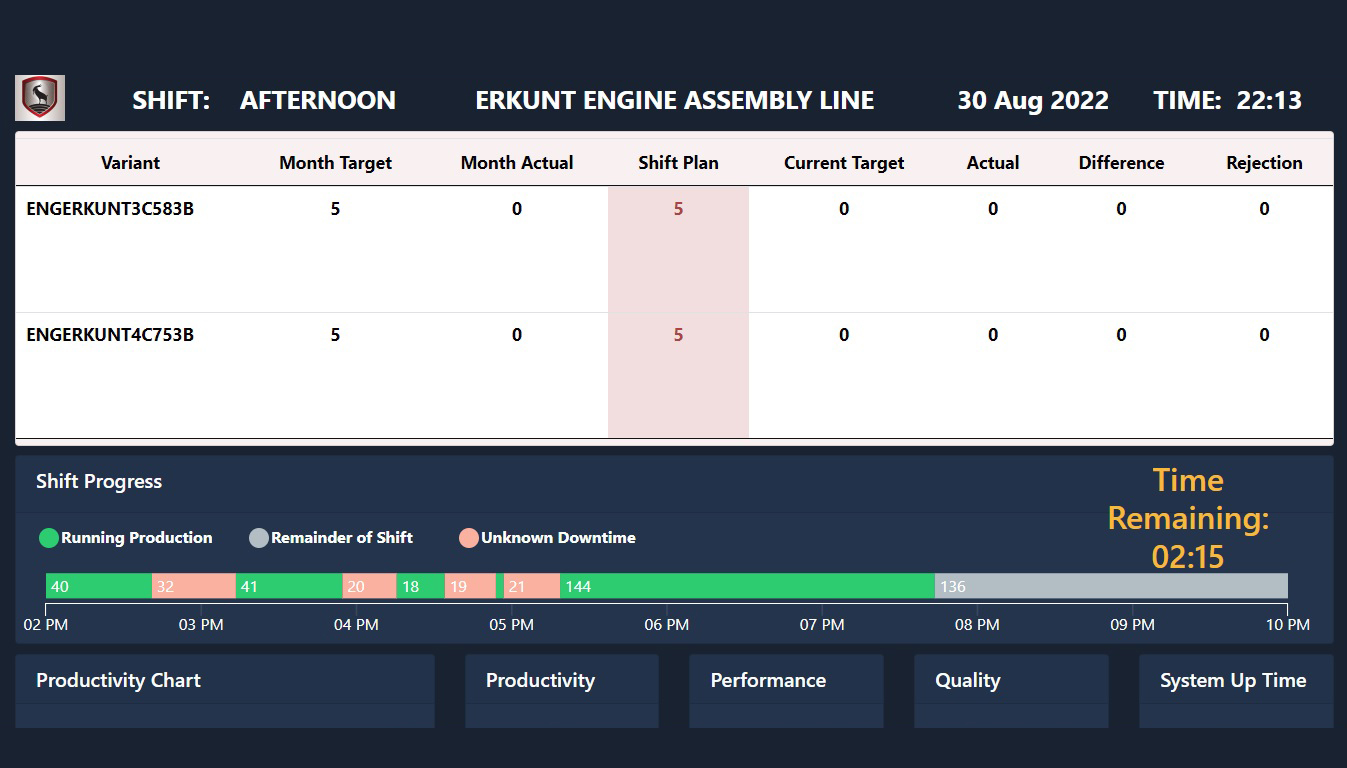

Solution 4 – Real-time reporting:

The detailed reporting functionality provides full transparency and traceability for each assembled engine, allowing the customer to easily analyse the root cause should an error occur. The customer can log in to the system and get a real-time production report for the day or shift straight from the line. Should a problem arise, the customer can take immediate corrective action.

Conclusion

ODIN Workstation has proved to be the ideal integrated digital solution to error-proof Erkunt’s first manual assembly line for tractor engines. This digital/manual combination has met the customer requirements effectively and surpassed expectations.

Providing comprehensive operator guidance in the local language ensures that every engine is assembled accurately and efficiently, while the built-in process security and data traceability also provide assurance that a quality product has been manufactured.

“The ODIN system ensures the correct completion of the engine assembly. The best part is the detailed report provided by the system. With this solution, we are able to see all the steps the engine went through during assembly, and all the process data from start to finish. It informs us in a simple and transparent way, giving us the details of the assembled engine, and what is happening on the line.”

Tuğçe Karakuş, PLC Engineer, Erkunt