- Case Study

- Mercedes-Benz

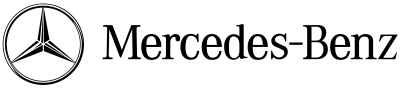

Axle Assembly Line

From push to precision:

Automating axle assembly

How driving innovation minimised downtime and improved quality.

- JENDAMARK DELIVERED

- East London, South Africa

About the Customer

The Mercedes-Benz South Africa (MBSA) manufacturing facility in East London, South Africa, is part of the global production network for the Mercedes-Benz C-Class, and is the sole global producer of the C-Class sedan for both left- and right-hand drive export markets. The plant, which has been assembling vehicles since 1948, has undergone significant expansion and investment, including the installation of new assembly lines, a logistics warehouse, and a solar plant to support its sustainability goals. This axle assembly line was Jendamark’s second project for MBSA.

Key Challenges

The major challenge was integrating a fully automated bush assembly process with the main Mercedes-Benz axle line, which had not previously been implemented in South Africa.

- Challenge 1

The need for a zero-downtime concept to prevent costly interruptions on the main assembly line.

- Challenge 2

Taking precise dynamic measurements of the axle during the bush pressing process to ensure correct positioning of components.

- Challenge 3

The manual push trolley line was previously associated with handling errors, inconsistent assembly, operator fatigue and other risks.

- Challenge 4

Integrating the line to ensure adherence to existing Mercedes-Benz standard (Integra) and compatibility with third-party equipment.

- Challenge 5

Integrating existing third-party equipment, which meant ensuring compatibility between the existing wheel alignment machine and the new assembly line equipment to avoid disruptions.

- Challenge 6

Enhancing the accuracy of the tightening processes to meet stringent ergonomic, safety, and quality requirements.

Our Solution

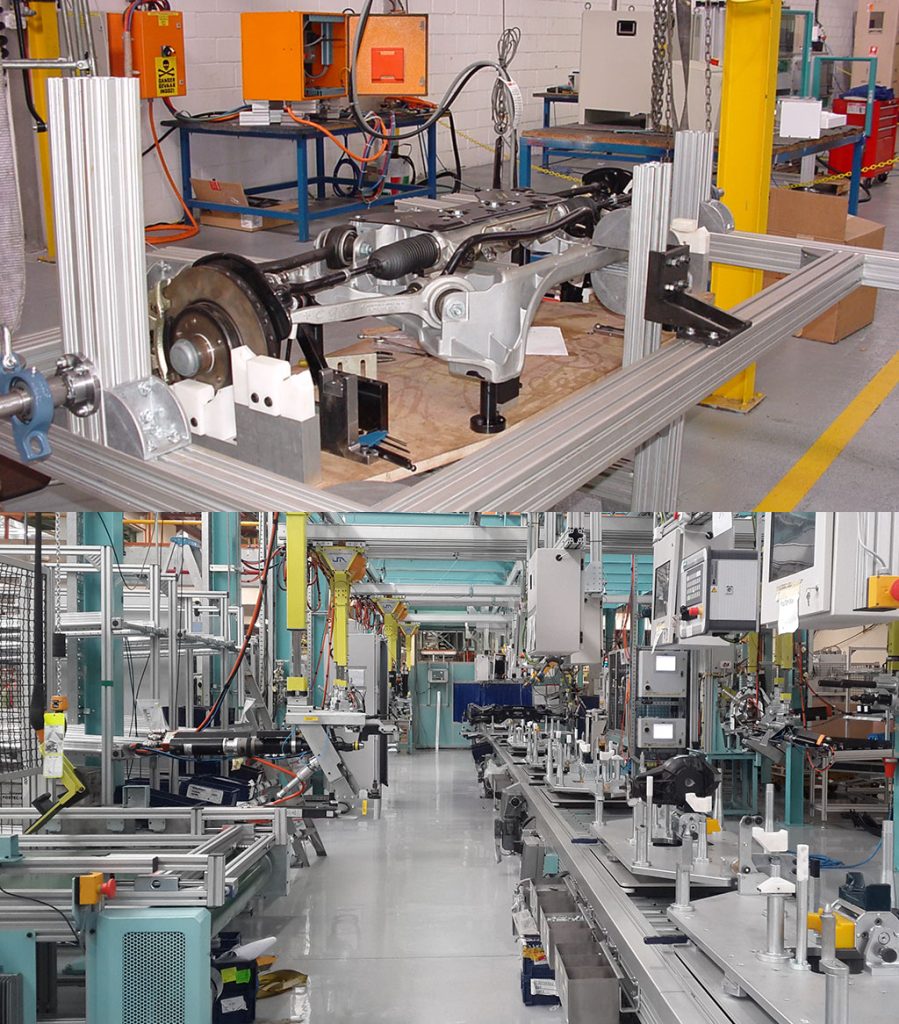

Jendamark implemented a complete front and rear axle assembly line and the first fully automated bush press assembly machine for Mercedes-Benz South Africa. This innovation aimed to reduce manual operations and their associated errors, improve efficiency, minimise downtime and enhance quality control in the production process.

Assembly Line Solutions

- Solution 1

Upgraded from push trolleys to an automated conveyor system, which improved consistency and accuracy of assembly, and minimised errors associated with manual handling.

- Solution 2

Designed a just-in-time and just-in-sequence assembly process to streamline the supply of axles to the main final assembly line.

- Solution 3

Designed the line to adhere to specific Mercedes-Benz (Integra) standards for compatibility with existing systems and integrated third-party equipment seamlessly.

- Solution 4

Developed specialised bolting tools and manipulators with integrated safety features and precision torque control to enhance ergonomics and meet rigorous quality and safety standards.

Bush Press Assembly Solutions

- Solution 1

Supplied a dual robot cell that automatically pressed the critical mounting bushes into their axle carrier. Each bush was pressed in with a servo-controlled press that monitored force and displacement throughout the entire pressing process to ensure the highest quality.

- Solution 2

The bush press line was equipped with an advanced dynamic measurement system to perform real-time assessments and ensure precise, adaptive positioning of components during assembly.

- Solution 3

Provided a backup press machine for the main press cell. It also served as a rework station to press out failed bushes if required.

Customer Benefits

- Enhanced production speed and reduced labour costs due to automated conveyor systems and the automated bush press cell.

- Improved consistency and accuracy in the assembly process, minimising errors associated with manual handling.

- Reduced manual effort and enhanced operator comfort.

- Guaranteed consistency through precision monitoring of torque application as well as pressing processes, improving assembly reliability and quality control.

- Minimised inventory and ensured components arrived exactly when needed through the just-in-time, just-in-sequence line.

- Improved quality control through precise dynamic measurement for bush pressing.

Key Takeaways

Jendamark’s second project for Mercedes-Benz South Africa tackled the challenge of modernising axle assembly by introducing the country’s first fully automated bush assembly process. At the East London plant – the sole global producer of the C-Class sedan – the shift from manual push trolleys to a conveyor-driven, zero-downtime line brought major efficiency gains. Key hurdles included integrating precise dynamic measurement systems, ensuring seamless compatibility with the stringent Integra standards, and incorporating third-party equipment without disrupting production. The solution combined automation, advanced torque-control tools, and just-in-time sequencing to cut errors, reduce operator fatigue, and improve consistency. The result was faster production, enhanced quality control, and more reliable assembly processes, helping MBSA balance global demand with the highest levels of precision and safety.