- Case Study

- Electra EV

E-Axle Assembly

Streamlining EV axle assembly with full traceability

How Electra EV achieved zero quality complaints with ODIN Workstation

- JENDAMARK DELIVERED

- Coimbatore, India

About the Customer

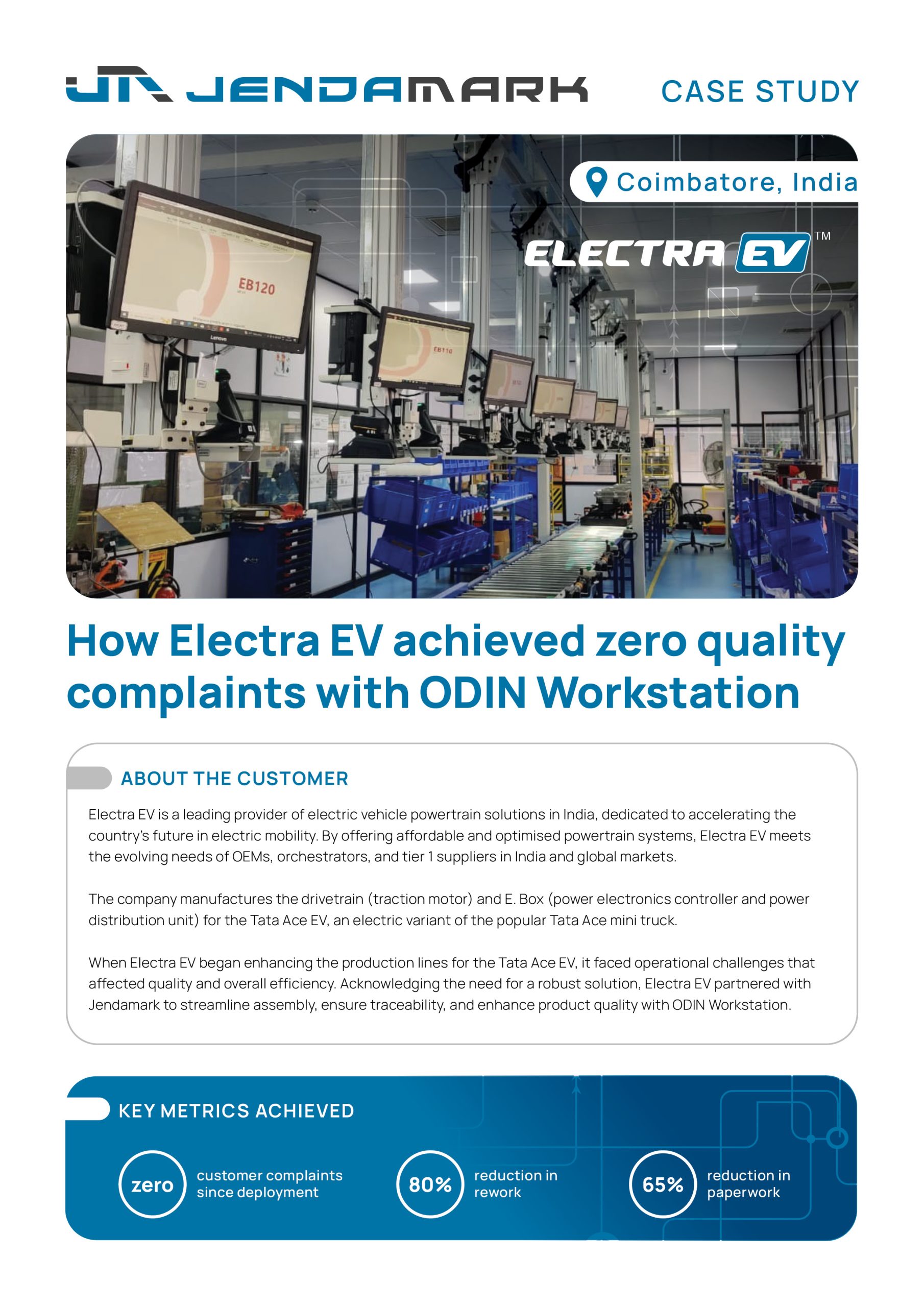

Electra EV is a leading provider of electric vehicle powertrain solutions in India, dedicated to accelerating the country’s future in electric mobility. By offering affordable and optimised powertrain systems, Electra EV meets the evolving needs of OEMs, orchestrators, and tier 1 suppliers in India and global markets.

The company manufactures the drivetrain (traction motor) and E. Box (power electronics controller and power distribution unit) for the Tata Ace EV, an electric variant of the popular Tata Ace mini truck.

When Electra EV began enhancing the production lines for the Tata Ace EV, it faced operational challenges that affected quality and overall efficiency.

Acknowledging the need for a robust solution, Electra EV partnered with Jendamark to streamline assembly, ensure traceability, and enhance product quality with ODIN Workstation.

Challenges

- Disconnected production lines

Electra EV operated two distinct assembly lines – one for the E. Box (12 stations) and another for the Drivetrain (3 stations). Without interlocking processes, parts could proceed to the next station even after failed or missed operations, leading to potential quality lapses.

- Lack of digital traceability

Traceability was an entirely manual, paper-based process, leading to critical issues such as:

- mix-ups at the packing station, with no way to confirm if all required steps were properly completed.

- missing or incorrect torque operations on bolted components due to the lack of a digital record or automated checks.

- inconsistent noise measurements that were manually recorded and not linked to specific parts.

- Quality concerns

Frequent customer complaints highlighted the negative impact of inconsistent assembly processes. Bolt tightening operations were sometimes missed or out of spec, creating reliability issues and driving warranty claims.

Our Solution

To address these challenges, ODIN Workstation was deployed across both assembly lines with the following key components and integrations:

1. Operating System and Process Security

- Operation guidance systems on all stations

These provide clear, visual, step-by-step instructions for each operator, ensuring that each torque sequence, assembly step, and measurement is completed correctly. - Interlock configuration

Stations now require the successful completion of previous operations before parts can move forward, eliminating the possibility of skipping critical steps.

2. End-of-Line Quality Assurance

- ODIN Ensure tablets

At final inspection, the tablets are used to capture images and digital signatures, linking results directly to each part’s history. - New auto noise testing machine

Automated and digitally tracked, the machine links test results to each specific part and eliminates manual recording errors.

3. Centralised Traceability and Control

- PLC integration with Atlas Copco bolting tools and leak testers

Every torque operation is automatically recorded, providing immediate feedback on pass/fail status. - Dot peen marking machines

Final part marking integrates with ODIN’s digital traceability, ensuring each product has a permanent and verifiable ID. - Line-side server and networking

Consolidates data from scanners, printers, and testers, facilitating real-time visibility and historical reporting of every part.

Customer Benefits

0 (zero) customer complaints

since deployment

Since implementing ODIN Workstation in November 2023, Electra EV reports zero product-quality complaints, underscoring a significant improvement in consistency and reliability.

80% reduction in rework

By catching assembly errors in real time and preventing defective parts from moving downstream, rework activities have decreased significantly, saving both time and labour.

65% reduction in paperwork

Comprehensive digital traceability and reporting have reduced the need for manual paperwork. Operators and supervisors now depend on real-time data, simplifying administrative overhead.

Enhanced operator confidence

and engagement

Visual instructions and guided workflows minimise guesswork and cultivate a more confident, skilled workforce. This systematic assembly approach helps maintain high morale on the shop floor.

Conclusion

Electra EV’s successful partnership with ODIN Workstation highlights the transformative impact of digital interlocks, real-time traceability, and automated quality assurance in electric vehicle powertrain assembly. By eliminating guesswork and manual errors, Electra EV not only enhanced overall product quality but also boosted operational efficiency throughout the organisation.

Key Takeaway

A structured, digitally integrated production line is essential for delivering consistent quality in the rapidly evolving EV industry. Electra EV’s experience shows that with the right solutions – such as ODIN Workstation – manufacturers can attain significant improvements in reliability, traceability and customer satisfaction without unnecessary complexity or superficial, sales-based approaches. It can work for brownfield and greenfield projects alike.