Drive Systems

Powertrain Assembly

Jendamark builds turnkey automotive assembly systems and production lines for all aspects of the powertrain system.

Every solution is designed to meet specific customer requirements and Jendamark strives to deliver the right fit for a particular market – offering a range of manual, semi-automated and fully automated solutions.

Explore our powertrain assembly line solutions

Axle Assembly

The axle has evolved from a simple torsion beam to a complex multi-link system, while modern axles include inverters and electric motors, as the push for hybrid and electric vehicles takes flight.

We specialise in front and rear axle assembly lines, including corner/knuckle assembly.

Jendamark has extensive experience with modular axle assembly lines. From pressing operations to tightening systems, our innovative solutions meet any requirement.

E-axles are significantly larger and heavier than traditional axles, due to the integration of the electric motor within the axle itself. While traditional axles typically weigh between 120 and 150 kilograms, e-axles can weigh upwards of 200 kilograms. This substantial increase in weight necessitates adjustments to our assembly processes and equipment.

In traditional vehicles, the engine is a separate component, with power transmitted through a shaft to the differential and then to wheels. With e-axles, the entire drive module is housed within the axle, offering improved efficiency and reduced complexity.

The additional electrical components require extra precautions to prevent damage from electrostatic discharge (ESD), such as ESD-safe work surfaces and grounding techniques, to protect these components during handling and assembly.

E-Axle Assembly

Multiple gears allow an EV to achieve better low-end acceleration and top speed, which could help to increase its range. The gears allow the driver to keep the power around a set amount, so that they can gradually speed up and slow down while still having sufficient torque.

We have provided an EV gear box assembly line featuring state-of-the-art automatic backlash checking of gear box, cotter pin insertion and other innovative solutions to meet our customer’s product requirements.

E-Gearbox Assembly

Our products meet the demands of the complex engine assembly process and ensure the flexibility to meet the needs of our individual customers, while attaining a high level of quality and safety.

Jendamark has decades of experience in engine assembly, from standalone machines to complete assembly lines.

As the internal combustion engine is evolving, so is our technology, while retaining the modularity of the system. Our cost-effective, turnkey solutions are designed to meet the increasing demand for standardised machinery.

Engine Assembly

The differential is a system that allows the wheels at each end of the drive axle to rotate at different speeds, which is required when a vehicle is negotiating a corner. Modern vehicles require quiet, strong, and reliable differentials, requiring a complex design and assembly process.

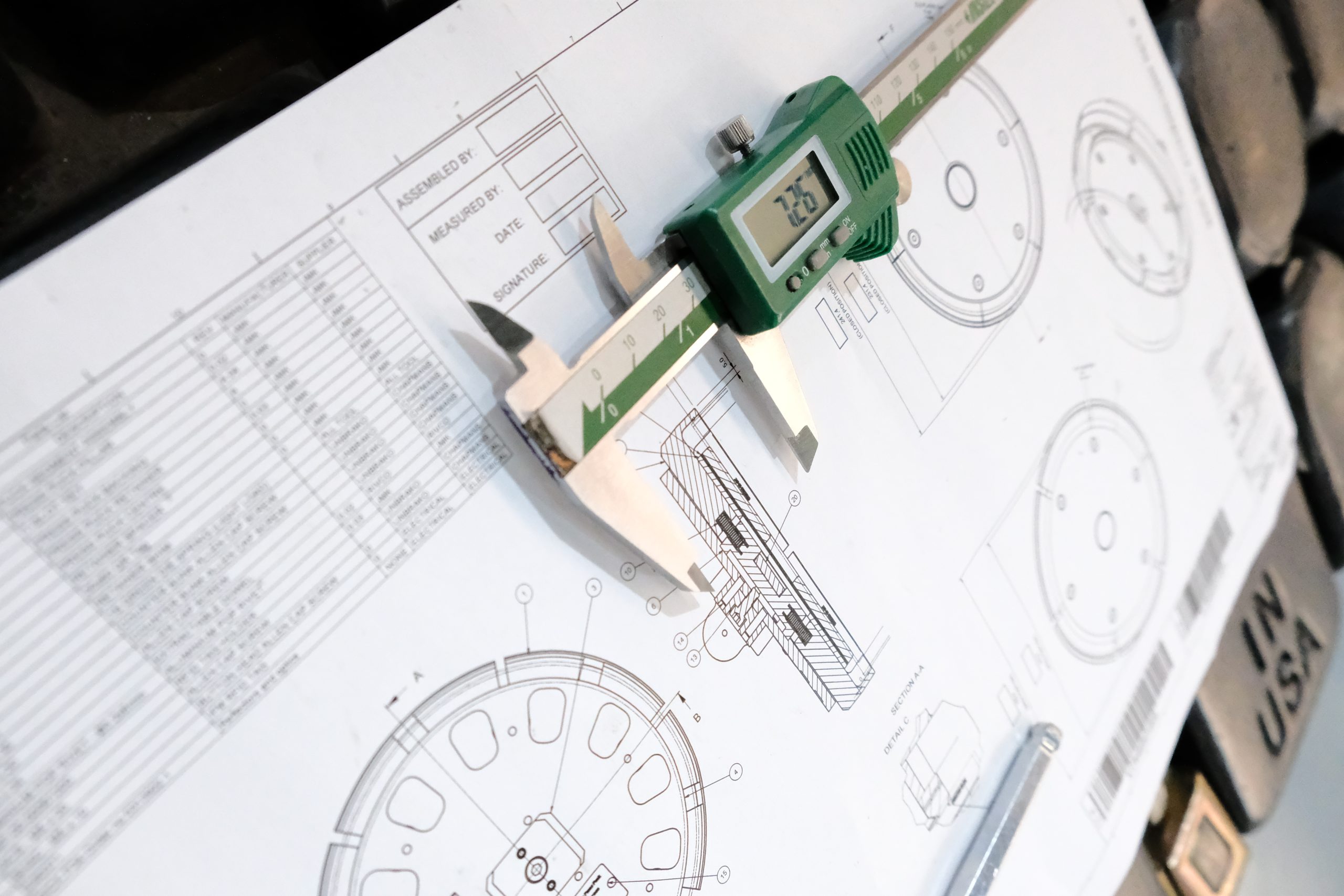

From intricate gauging to highly accurate measurement systems, our innovative solutions ensure accurate and repeatable assembly with the highest quality.

Jendamark specialises in standardised machines, adaptable to the customer’s requirements.

Projects delivered globally are a testament that the technology we deliver is of the highest quality and safety standards.

Differential Assembly

Enhance your critical assembly processes

See how Jendamark technologies – including high-precision tightening and measurement solutions – can set your final product apart.