How Atlantis Foundries Leveraged AI for Manufacturing Excellence

Introduction

The manufacturing industry has long faced challenges in quality control, efficiency, and predictive maintenance. Atlantis Foundries, under the leadership of CEO Peter du Plessis, has successfully integrated AI-driven predictive analytics to enhance production processes, improve quality, and reduce defects. This case study explores how AI has become a transformative tool for Atlantis Foundries, positioning it as a global leader in smart manufacturing.

Establishing a Robust AI-Powered Data Model

The Importance of Structured Data in AI

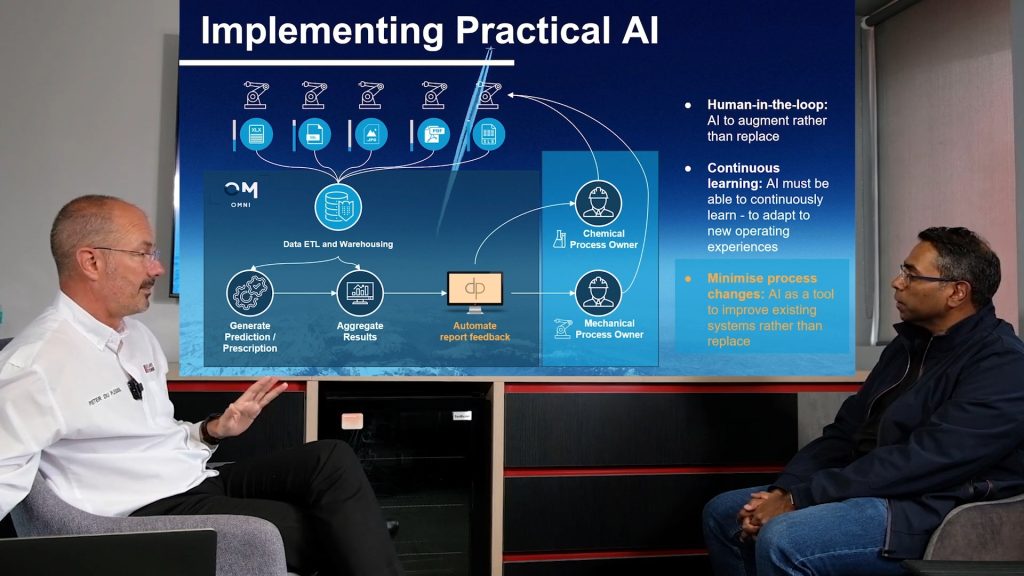

For AI to be effective in manufacturing, it requires structured and well-integrated data. Atlantis Foundries developed a comprehensive data model to capture and analyze vast amounts of production data, leading to improved decision-making and optimized manufacturing processes.

Key Components of Atlantis Foundries’ Data Model

- Standardizing Data Collection: Ensuring that all suppliers and machines provide data in a structured format.

- Integration with Equipment: Mandating that new equipment aligns with predefined data requirements.

- Building a Centralized Data Hub: Aggregating data into a unified big data model, which serves as the foundation for AI-driven insights.

Impact on Production Processes

With a structured data model, AI can efficiently identify patterns, detect anomalies, and predict outcomes. This capability enables Atlantis Foundries to streamline manufacturing processes and drive continuous improvements in efficiency.

The Role of AI in Predictive Quality Control

Challenges of Traditional Quality Control

Historically, quality control in foundries relied on manual inspections and analysis of historical trends. This approach often resulted in inefficiencies and increased defect rates.

How AI Enhances Quality Control

- AI-Driven Anomaly Detection: The system continuously scans over 6,500 production processes, identifying quality issues before they occur.

- Prescriptive Analytics: AI not only flags problems but also suggests corrective actions, enabling operators to make data-driven decisions.

- Near-Zero Defect Production: By leveraging predictive modeling, Atlantis Foundries has significantly reduced scrap rates and improved product consistency.

Peter du Plessis Insights on AI’s Role

Peter emphasizes that AI is not just a trendy concept but a practical tool that solves real-world manufacturing problems. The system has evolved from simple monitoring to prescriptive AI, where machines provide actionable insights to operators, significantly enhancing operational efficiency.

AI-Powered Cybersecurity for Data Protection

Importance of Data Security in AI-Driven Manufacturing

As manufacturing increasingly relies on AI and cloud computing, data security has become a critical concern. Atlantis Foundries has implemented advanced AI-driven cybersecurity measures to protect sensitive production data and prevent unauthorized access.

Cybersecurity Measures Implemented by Atlantis Foundries

- AI-Powered Network Monitoring: The AI system continuously scans for unusual traffic patterns and potential security breaches.

- Access Control and Authentication: Any new device attempting to connect to the network is flagged and blocked unless properly authorized.

- Cloud Computing Integration: Secure cloud storage solutions ensure that critical production data remains protected from cyber threats.

Balancing AI Adoption with Security Considerations

By implementing a security-first approach, Atlantis Foundries ensures that AI adoption can scale without compromising data integrity. The combination of AI-powered monitoring and strict authentication protocols helps safeguard the company’s digital infrastructure.