- Case Study

- FAURECIA

Catalytic Converter Assembly Line

Building blocks for engineers: Save time and money. Ensure consistent quality.

How our building block approach cut Faurecia’s canning line project costs by 20% and operator training time by 50%

Jendamark worked closely with Faurecia to develop a set of building blocks for its canning lines globally, and each machine was designed, verified and tested with the customer. Therefore, we knew that each building block was working well and meeting the right quality and safety standards, so we could piece them together with confidence.

We have delivered more than 40 production lines to Faurecia using these proven concepts.

- JENDAMARK DELIVERED

- WORLDWIDE

About the Customer

Faurecia is a leading automotive technology group and global top 10 Tier 1 supplier with a multi-billion-euro annual turnover. Its Clean Mobility Division comprises 20 plants worldwide, manufacturing exhaust systems and catalytic converters.

Although this case study is specifically for catalytic converters, the same concept has been applied on axle assembly and differential assembly lines, allowing Jendamark customers to enjoy the benefits of our custom building blocks.

The Scenario

Typically, customers order bespoke assembly lines designed to the specific requirements for a particular product. Because the line is not flexible, the customer is often unprepared for future product variants or to adapt to changing demands.

Fluctuating product volumes also create problems.

When volumes are down, the asset isn’t being fully utilised because it is designed to build that particular product. Similarly, when volumes go up, the customer would have to buy another identical or similar assembly line to accommodate the increase – they couldn’t simply put the additional volumes on another machine that had capacity.

- Challenge 3

Depending on the location and volumes, as well as budgetary constraints, some production lines had to be manual, while some needed to semi-automated, and others fully automated.

- Challenge 4

People come and go in both the customer and supplier’s organisations, so the shared methods and processes needed to be standardised to ensure continuity.

Challenges

- Challenge 1

The assembly processes were complex and different from one another, so combining then into one type of production line would be difficult.

- Challenge 2

Previously, every production line had to be vetted individually and specifically for a particular process. Because there was no standardisation within each of those lines, and because every element was different, the sign-off process was very complex.

Customer Requirements

The customer needed to be able to handle different assembly processes on its canning lines and deliver a variety of products:

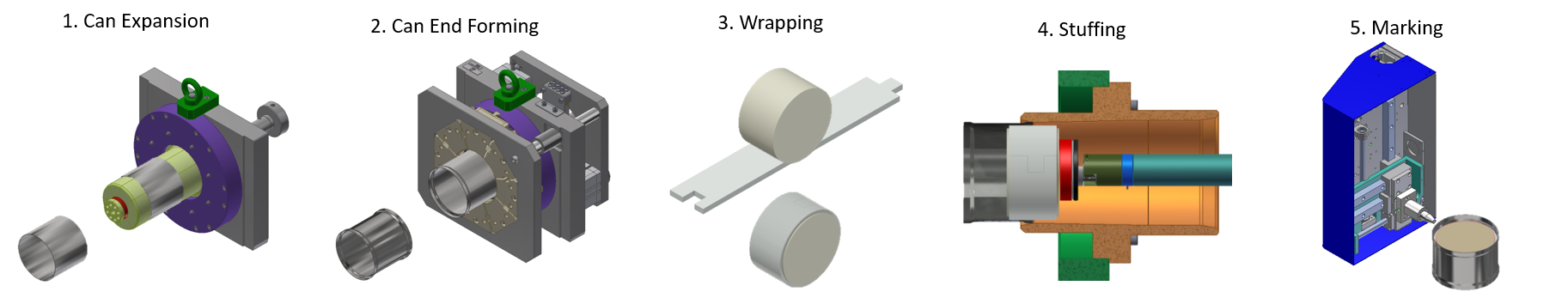

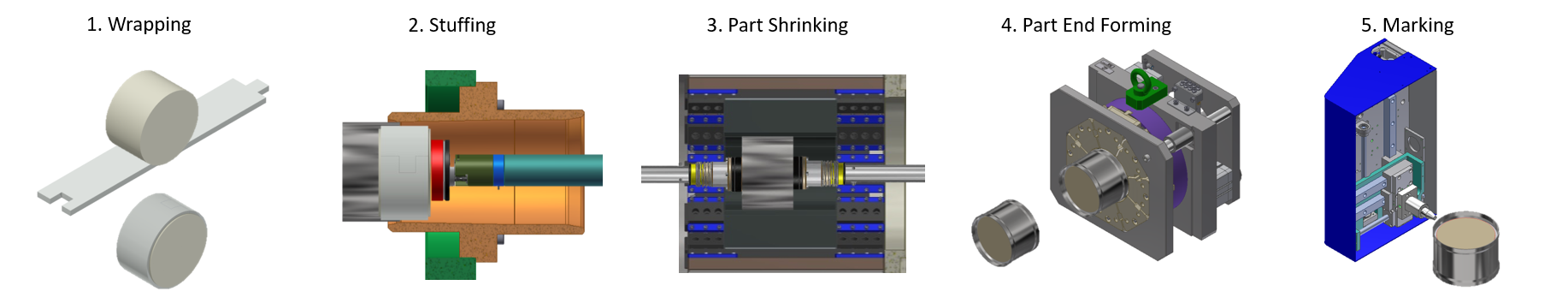

Processes Required

Pre-sizing (hard stuff process)

The empty tube is formed before stuffing it with the mat and monolith.

Post-sizing (soft stuff process)

The tube is first stuffed with the mat and monolith before forming.

Products Required

Single-brick assembly

One mat and one monolith are pressed into a single can

Double-brick assembly

Two mats and two monoliths are pressed into a single can

Triple-brick assembly

Three mats and three monoliths are pressed into a single can

Our Solution

Jendamark designed and developed a set of building blocks – verified and vetted by the customer – that could be reconfigured in multiple ways to meet specific requirements and handle various processes including hard stuff, soft stuff, automated, semi-automated and manual.

Each building block formed a piece that fitted into the particular puzzle for a particular scenario. A major advantage was that they could be taken apart again and reused in different set-ups into the future. Being able to reuse these building blocks has become a huge cost saver for the customer over the years.

After working with Faurecia for more than a decade, developing and progressing every year, we landed on a flexible layout with some additional building blocks that allowed us to cater for pre-sizing, post-sizing, single-brick, and double-brick assembly.

Customer Benefits

1. Cost-saving

Standard building blocks can be reconfigured in different ways to make up the lines for the various processes, and reused in other lines in future.

2. Simplified sign-off

Because the lines are made up of standardised elements, the sign-off is less complex.

3. Varying automation levels

The building block lines can accommodate varying requirements for manual, semi-automated or fully automated assembly.

4. Training efficiencies

Because the building blocks are standardised, training of both operators and maintenance technicians is less complex. Because the machines are similar, teams can identify and respond to problems faster once they are familiar with the basics.