In this article, we spark an important conversation about the underestimated impact of ESD on safety and quality in your production facility.

We all know that tiny jolt, commonly known as ‘static’, that you feel when you touch a metal doorknob or, sometimes, even another person. To us, it might be harmless but, in a factory, a much smaller discharge (one you might not even feel) can destroy an electronic component in an instant. Or damage it in such a way that leads to product failures over time.

ESD occurs when a charge imbalance between two objects suddenly equalises, often through a spark. For manufacturers, it is not only a quality issue but a safety issue too. It is not just about damaged products; in some environments, ESD can even ignite flammable substances.

When it comes to ESD, here’s why the following industries have no margin for error and cannot afford to be complacent:

Strict ESD protection standards (such as ANSI/ESD S20.20) for industry do exist. But the issue is bigger than regulatory non-compliance. For affected industries, neglecting ESD control as an important aspect of your manufacturing operations can lead to some serious issues.

While a damaged circuit board might not fail immediately, it could cause malfunctions and lead to product failures down the line, which ultimately hurts your brand reputation, customer relationships and bottom line.

Financial losses are keenly felt, with billions lost annually due to ESD-related defects and product recalls across the globe.

Ultimately, the safety risk for certain industries, where ESD can cause explosions or fires, cannot be overstated. The human factor and protecting employees should be of paramount concern.

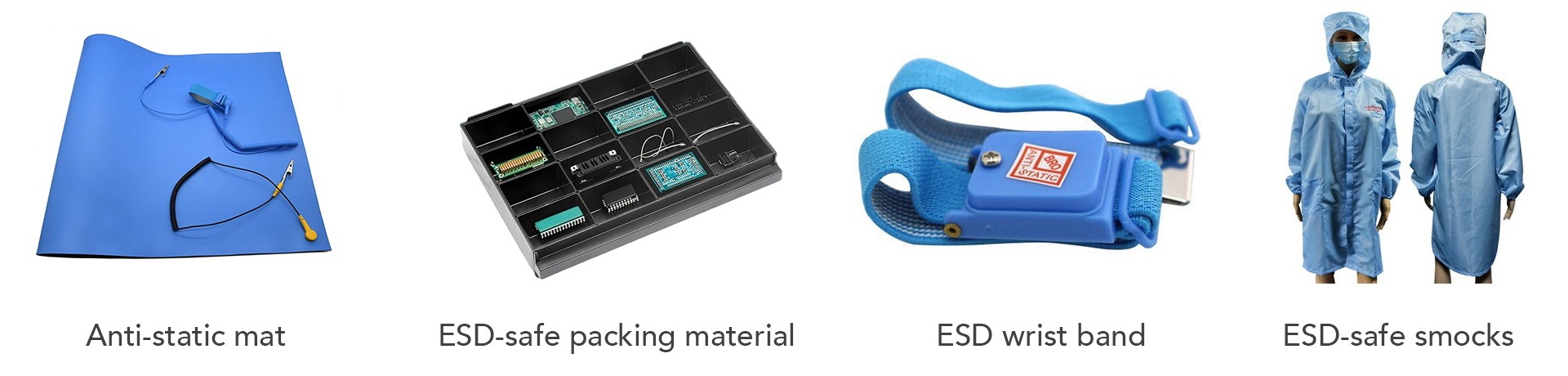

There are multiple tools and products available that manufacturers can invest in for effective ESD prevention.

In fact, in an increasingly digital world where electronics plays a central role, “the overall demand for ESD protection devices is projected to record a [compound annual growth rate] CAGR of 4.1% between 2023 and 2033, totalling around 3,965.5 million

US dollars by 2033.”

(Report: Future Market Insights)

Some examples include:

In the world of high-tech manufacturing, ESD isn’t an afterthought – it’s a mission-critical factor. Without proper protection, entire production lines could be compromised. As factories become more advanced, the need for ESD safety only grows. Investing in prevention today means securing product integrity, worker safety, and business continuity for the future.

Electrical safety is a particular concern when it comes to EV battery pack assembly. Read more about the testing and other critical assembly processes that Jendamark uses to ensure safer EV battery pack assembly here.

Check out our other Resource sections:

Sign up to get the latest thought leadership articles – written by our experts – delivered straight to your inbox.